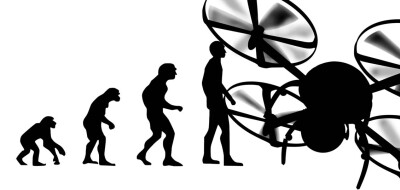

The potential around how drones might impact construction projects of all types and sizes have made headlines across the world, but those headlines often raise more questions than answers. What does the use of drone technology look like specifically? What does it mean to use a drone within something like a construction tunnel environment? How are professionals measuring the impact of the technology?

Luckily, those are the exact questions that are being answered on the largest construction project in Europe. Crossrail is currently working on a new railway that will become known as the Elizabeth Line when it opens through central London in 2018. The massive civil engineering & infrastructure project has Engineering enterprise Laing O’Rourke as one of its tier 1 contractor covering 3 major stations.

The logistics of this process are set to be explored and detailed during the UAVs in GPS-Denied Tunnels for Crossrail Project session at the upcoming Commercial UAV Expo Europe. It’s a topic with implications that will resonate with numerous professionals across the world.

Drone Adoption and Benefits

Crossrail Limited is a wholly owned subsidiary of Transport for London (TfL) and is jointly sponsored by TfL and the Department for Transport. Once the railway is complete it will be handed over to TfL and run as part of London’s integrated transport network. As Project Engineer - Tunnels and Platforms - at Laing O'Rourke, Ravintheran Kugananthan has been intimately involved in the process to add a new dimension to this integrated transport network that runs throughout London.

How drones could impact a project of this type was something that came to Kugananthan’s attention after the construction team at the Liverpool street project was challenged by their project director to increase efficiency and identify safer methods of construction. After examining the business case, the whole team saw the potential, and stakeholders in different parts of the organization were able to quickly see how this kind of innovative technology could make a difference.

“Our project stakeholders are quite open to innovation and could clearly see the benefits of the use of the drone,” said Kugananthan. “The Liverpool street station has been an exemplar site for innovation and has been able to employ many new technological advancements to increase efficiency and safety.”

You can see the specific advancements Kugananthan is referencing in this video, which highlights the number of ways drones are used. The team has been able to send these tools into otherwise inaccessible areas and get a closer look at the pipes and services. They’ve also helped with the communication between team members.

As important those applications are, they’re notoriously difficult to measure. Are there more direct ways the team has been able to quantify the kind of differences the technology has created?

Quantifying the ROI

The company’s use of drone technology has created a tangible cost saving for their inspections, but the greater focus was on the reduction of personnel working at height expose to risk. However, they recognized the need and importance of measuring how and where these tangible cost savings were being created.

Consider the following breakdown that showcases the differences and distinctions between the costs associated with the inspection of a concrete pipe with a drone versus the inspection of that same pipe using traditional methods.

Task – Inspection of Concrete Pipe on side of 45m shaft (once a week inspection )

Previous inspection regime:

- Time: approximately 1 hour to do a visual inspection in shaft

- Labour requirement : 4 personnel ( Crane driver , Slinger signaller , Crane supervisor , Site engineer)

- Using a caged man rider with Slinger signaller & Engineer inside the tower crane will lower the cage parallel to pipes to the base of the shaft at a slow pace, videos and photos are take for record purposes and examined for cracks, damage and loose fixingsMethod:

- Labour cost: 4 personnel 1 hour: £149Cost Consideration

Current inspection regime with Drone

- Time: approximately 15 minutes to do a visual inspection in shaft

- Labour requirement : 1 personnel ( Site engineer)

- Method :

- The drone is taken to the bottom of the shaft and is flown 2m away from the pipes vertically to the top and returned back to bottom ( Engineer will remain at base of shaft throughout flight) , videos and photos are take for record purposes and examined for cracks , damage and loose fixings

- Cost consideration :

- Labour cost: engineer @ approx £35 per hour: £ 8.75 for 15min

- Plant Cost: £ 45 per use (based on how many times the drone was used for this particular inspection)

Total Saving:

- = £375.25 saving per inspection

- = £1501 per month

Those details come straight from Kugananthan himself, and showcase exactly how and where the company sees the difference drones can create for them on their bottom line. It’s also a great illustration of what it means to utilize a drone in place of a traditional tool or approach.

New Opportunities

While regulation poses ones of the biggest challenges to utilizing drone technology, those considerations don’t present as big of an issue for uses like this since there is no exposure to public or other aviation air traffic on account of the entire project taking place underground. It’s a reminder of the fact that regulation doesn’t always present a significant barrier to entry.

Based on their current usage on Liverpool Street, the team at Laing O’Rourke has put together a lessons learned document that will help other sites utilize the technology when applicable. That document includes details associated with current regulations requirements, what equipment and accessories are needed as well as techniques for flying in GPS denied areas and high magnetic ferrous metal areas.

These are details that are critical to how the organization can and will use drones, and they’ve already had Laing O’Rourke Projects in Australia and Hong Kong rely on these documents and experiences. It’s just the beginning for how the company can and will be adopting drone though.

“We have been working with Topcon and Soluis to use the Falcon 8 Drone to capture photogrammetry and Terrestrial LiDAR scans within the tunnels,” Kugananthan mentioned. “Once the cloud data and information have been processed, a VR environment will be produced to enable accurate measurements taken in VR. This is a new concept and has great potential.”

The potential Kugananthan is referencing is obvious, as the ability to view, augment and adjust these kinds of VR environments will enable all sorts of opportunities while ensuring crews stay safe without creating additional logistical expenses.

The bottom line difference UAV technology can make today in construction tunnel environments is quantifiable, but the true potential of the technology is just beginning to be explored. That makes it more important than ever to understand what’s working today in order to open up brand new applications in Europe and across the world tomorrow.

Comments