While updates with cybersecurity and innovations like the PRISM Lite got people talking at AUVSI’s XPONENTIAL 2023, far and away the biggest news was around Percepto receiving an FAA waiver to operate beyond visual line of sight close to structures without ground-based systems. With this waiver, the company has defined what it can actually look like to scale true BVLOS UAS operations for inspections and monitoring.

There are some limitations associated with the waiver, as low risk "shielded" BVLOS operations are authorized 200 feet above and around assets located on critical infrastructure sites. At non-critical infrastructure sites, shielded BVLOS operations are permitted 50 feet higher than the tallest obstruction located within a half-mile of the site. Even with those limitations, this waiver opens up a world of possibility for users and the drone industry as a whole.

Some of these possibilities were discussed by Percepto customers during the Inspection Automation Case Studies from Four Industry Giants session that took place at XPONENTIAL. Moderated by Ariel Avitan, Chief Commercial Officer & Co-founder at Percepto, the panel talked about the advantages that drones have enabled for them, how they measure improvements to their bottom line, what kind of a difference the technology made for their established cost per inspections models, and more.

The panel was joined by Christopher Doherty from the FAA, whose work as an Aviation Safety Inspector was part of the process to get the BVLOS waiver approved. In breaking down how and why this waiver was approved, Doherty mentioned it was all about taking a risk-based approach to ensure that the safety of the NAS would not be compromised. He talked about what it meant for Percepto to demonstrate to the FAA that their solution would be able to operate BVLOS close to structures safely without ground-based or airborne DAA systems.

Each of the end users on the panel had a different story to share about how they got up and running with drone technology and where they were with adoption and integration, and Heath McLemore was able to share various element of this journey for his company. As the Flight Operations Manager for the Florida Power & Light AIR (Aerial Intelligence Response) team, he is intimately involved with the 400-600 UAS flights they conduct each day to maintain inspections of over 75,000 miles of power lines within the state of Florida. This developed program is the result of efforts to operationalize drone flights that goes back to 2018. In those early days, the team envisioned how the technology could be used to reduce costs and decrease inspection time, but for them, the foundational value proposition was about something else.

“We’re always looking for ways to automate redundant tasks but for us, safety is the main focus and ultimate value,” McLemore said. “That defined our adoption and expansion of the technology, which we’ve always positioned in a very specific way internally and to our customers. I always say that I run an aviation program, but instead of planes, it's drones.”

Michael Hull is the Director of Generation Technology, Fossil, Solar & Storage at Vistra Corp., which is a leading power generation company in the United States. He talked about the incredible difference drone technology has made on the solar side. The company previously contracted out inspections once a year but knew they needed to perform them more frequently. However, performing those inspections four times a year would mean four times the inspection cost, which wasn’t going to work. The autonomous capabilities of Percepto's AIM platform allowed them to redefine the pricing model of inspection work.

“The technology has allowed the cost per inspection model to completely flip,” Hull said. “It’s changed the value proposition for us because it allows our teams to prioritize fixing things rather than assessing or inspecting.”

Danny Allen is a Geospatial Intelligence Supervisor at ConocoPhillips, where he oversees geospatial analysis methods and ensuring the accuracy of data and intelligence products. His team used drones to supplement their imagery needs at first but then moved onto inspections. That process opened up many people’s eyes to the opportunities the technology presented in terms of different ways they could be capturing data and performing certain tasks, many of which they hadn’t envisioned at the beginning of the process.

“We really wanted to increase operational efficiencies,” Allen said. “For us, it was all about giving the data back to define actionable insights.”

Tim Shanfelt is the Operations Enablement Director for Koch Ag and Energy Solutions. He talked about how his team has used drones the last few years to eliminate work that falls into one of the three “d” categories: dirty, dangerous, or disinteresting. The autonomous element of the technology has been huge for his team, as it has freed up chunks of work that can now be scheduled. It keeps people out of harm's way, but also leads to better assessments that they’ve started sooner than they would have been able to via traditional approaches.

"The flip of cost to value is huge,” Shanfelt said. “Instead of looking at reports in terms of costs, once the system is in place, it's a question of how can we unlock more value. And that's freed us up to look for those value opportunities.”

Shanfelt also mentioned how useful the AIM system is to his teams in terms of the reports they get, which underscores that it’s just as much about the software and ecosystem as it is the drone. Each of their sites is a bit different, and having the team and solution work with them where they’re at has made all the difference in the world.

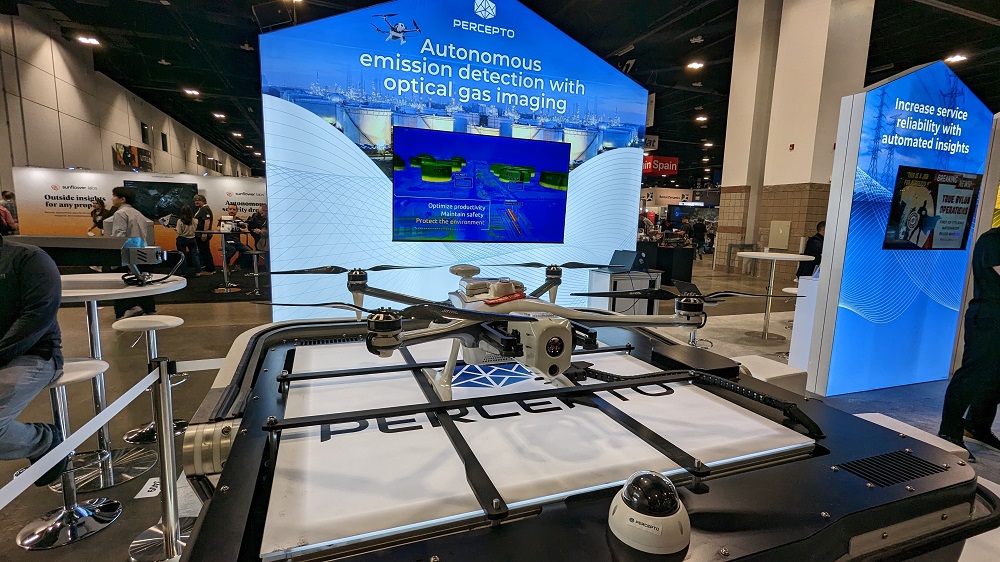

Being able to move past questions about cost structure and instead focus on the additional opportunities that the technology represents is a core component of the value that can be opened up at scale, which is something that has literally been talked about for years now. These use cases provide answers when it comes to the technology, regulation, and applications that are creating that value, which the Percepto team further demonstrated with a live demo at their booth.

Allowing inspections to occur remotely from anywhere in the United States changes the paradigm around how and when inspections are performed. Large scale adoption of drone technology is a vision and goal that many have talked about in the drone industry, but the specifics associated with what that would mean in terms of technology, regulation, and application were always ill-defined. These use cases, as well as the waiver Percepto received, should encourage innovation across the industry in a whole new way, finally fulfilling the promise of the value of the technology at scale.

.jpg.small.400x400.jpg)

Comments