Over the years, drones have consistently proven their value to surveyors working in a variety of environments. The ability to gather aerial data with many kinds of sensors has opened up a whole new set of data and insights. From mapping treacherous terrain to gathering data underground in GPS-denied areas, drones have been helping surveyors capture clear and insightful data for years now. As drone-based surveying has caught on, there have been some great advancements in sensor technology.

GPS-Denied Sensors

One of the biggest breakthroughs the industry has seen over the last few years is the introduction of sensors that function in GNSS-denied areas such as tunnels, mines and the interior of concrete buildings. This has become an essential tool for conducting inspections in bridges and tunnels where surveyors are either completely underground or their signal is blocked by the bridge or surrounding infrastructure. These types of critical infrastructure require surveys to check for structural integrity or water ingress. Before the use of drones with these special sensors, crews would have to do a manual inspection, forcing them to climb high scaffolding and come face to face with the problem area, and dangerously gather data at a slower pace. Using drones has made this task far safer and allows crews to gather more data faster. This article is a prime example of how a GPS-denied sensor was a game changer for conducting underground inspections in Norway.

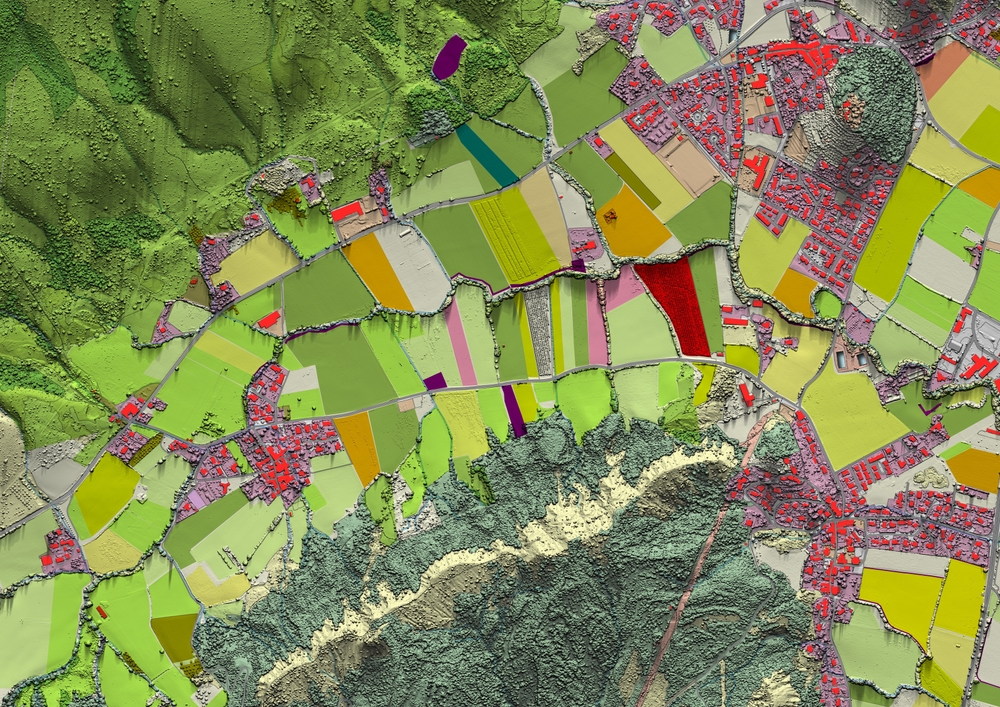

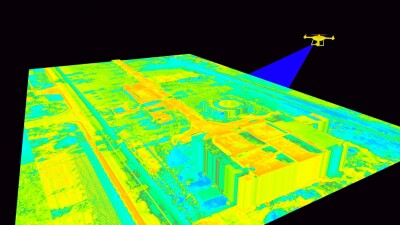

Sensor Fusion

Sensor fusion has been another great advancement in a surveyors’ toolkit. The option to fly once and capture imagery, lidar data, and thermal or multispectral data all in one flight is a huge improvement from flying separate missions to gather a single data type. Considering the fact that all sensors are time-synchronized and position-locked with real-time kinematic positioning (RTK), each data point is accurate to each other. This means less time cleaning up data post-flight and better integration into other technologies. This process has been widely adopted by construction, forestry, and utility companies due to the large areas they need to survey. This article provides high-level insight on how sensor fusion is transforming spatial data collection.

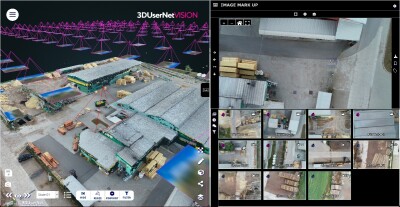

Automated Data Interpretation

Last but certainly not least is the adoption of AI for organizing and interpreting data points. In this context, AI for drone surveying means the computer is self-sufficient in identifying objects and defects, recognizing patterns in imagery and point clouds, and automated classification and change detection across large datasets. Essentially, AI platforms have been adopted to take the first pass at surveying data, saving personnel days of work. Most of this efficiency can be found immediately after a flight where AI is responsible for automated processing.

Automated systems such as these can be met with some resistance, as they can be viewed as potentially replacing a human in the process, but today it is mainly used for those tedious data-related tasks to free up workers for other aspects of the job. It’s important to note that AI does not have the same credibility as a licensed surveyor. AI is most effective when used in tandem with oversight and sign-off from a human professional. This case study shows just how a utility company leverages AI to analyze inspection data totaling 20 million images a year.

These are just a few examples of new technologies and practices that represent a fundamental shift in what drone-based surveying can achieve. These technologies are maximizing efficiency in workflows by cutting out unnecessary time spent on small details and allowing survey teams to focus on validation, analysis, and decision-making rather than manual processing.

Comments