Seven years ago, Massachusetts-based Windover Construction began flying drones to capture comprehensive data of its sites to increase operational efficiencies. Since then, the full-service construction and management firm with an industry-leading Virtual Design and Construction capabilities has expanded the ways it uses—and derives value—from uncrewed operations.

“We were one of the very early implementers of drone technology in construction,” Amr Raafat, Windover’s Chief Innovation Officer told Commercial UAV News. “We decided to implement drones for many reasons, and some of the biggest reasons were mitigating risk and having the ability to capture data in ways that are less time consuming and more efficient.”

Raafat explained that drones are ideal for getting information on major construction sites. “We work on large, multifamily sites that can be as large as 20 acres,” Raafat said. “We found that using drones with laser scanning technology is a lot less time-consuming than going on the ground to capture data. We saw that drone technology can really be much more efficient in very large areas, as well as a hard-to-reach areas.”

On recognizing the effectiveness of uncrewed systems, Windover decided to expand its drone operations. “We wanted to take things further and do more than mapping sites,” Raafat stated. “We were more interested in capturing detailed data and highly accurate dimensional information to document what’s built onsite in real-time. We’ve been adding latest cutting-edge systems, such as lidar drone sensors, to our existing UAV workflows.”

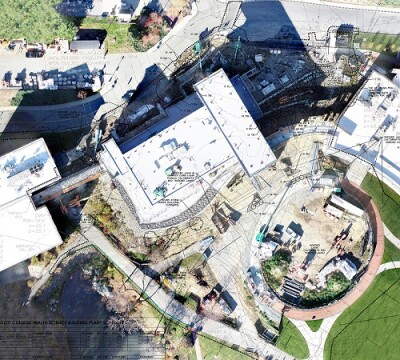

At Endicott College New Academic Center, Windover utilized drone lidar technology and utilized the drone data to build detailed Autodesk Civil 3D model to help coordinate the new foundations with the existing ledge and complex site topography. In addition to Windover documenting the whole Endicott College campus with drone scan to provide detailed building envelopes and overall topography grades data to support the campus future planning projects.

At Endicott College New Academic Center, Windover utilized drone lidar technology and utilized the drone data to build detailed Autodesk Civil 3D model to help coordinate the new foundations with the existing ledge and complex site topography. In addition to Windover documenting the whole Endicott College campus with drone scan to provide detailed building envelopes and overall topography grades data to support the campus future planning projects.

Adding these systems has produced substantial value for Windover and their clients to demonstrate how the combination of uncrewed vehicles and sophisticated imaging systems have helped construction operations, Raafat described work on installing plumbing systems at large multifamily construction sites.

“Windover is known as a leader in building modular and prefab projects, and installing underground pipe systems is an important part of many of our project’s operations,” he said. “We use drones with ground control points to capture data of the as-built pipes, to perform real-time QA-QC overlays with the first-floor plan to detect any discrepancies before pouring concrete slabs. To avoid costly delays.

Conducting these operations before concrete foundations are poured has helped Windover save significant time, money and on time with high quality work especially in large multifamily and academic projects. “It is critical to do this work before pouring concrete because at that point it’s very easy to move things around and make adjustments based on discrepancies found in the overlay,” Raafat stated.

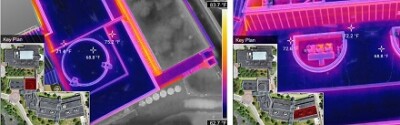

Another example of how Windover uses drones to add value to its projects concerns the inspection of existing, culturally significant buildings. “We worked on an inspection of the façade of a historic building in downtown Boston with a logistically challenging site,” Raafat explained. “Our use of drones offered the safest and most efficient solution while minimizing disruption at the busy site. With our drones, we quickly inspected the façade and captured dimensional and thermal data. We mapped the facade, collected high-red thermal info as well, to see if the building was losing any heat, missing insulation in envelope or other leaks.”

Using drones to perform thermal inspections can result in large, long-term benefits for builders and owners. “With a drone, we can inspect a building at different times of day, like right after sunset, to locate the areas that required fixes to improve the building energy performance and its long-term sustainable aspects. We can capture data of large building complexes in a fraction of time compared to ground-based inspection. and then our drone thermal reports help to guide the ground investigation by locating exact potential issues. These drone-based solutions can make a huge impact on the sustainability and energy performance of the building,” Raafat said.

Using drones to perform thermal inspections can result in large, long-term benefits for builders and owners. “With a drone, we can inspect a building at different times of day, like right after sunset, to locate the areas that required fixes to improve the building energy performance and its long-term sustainable aspects. We can capture data of large building complexes in a fraction of time compared to ground-based inspection. and then our drone thermal reports help to guide the ground investigation by locating exact potential issues. These drone-based solutions can make a huge impact on the sustainability and energy performance of the building,” Raafat said.

These applications and many others demonstrate how Windover has embraced and expanded the use of uncrewed technology in its construction work. The application of drones and related systems have added cost savings, efficiency, and improved safety to Windover’s operations—it has earned the company recognition from the global AEC industry community.

In 2022, the company received the Autodesk Excellence Award for Accelerating Transformation for “using state-of-the-art technology to remodel the historic Cabot Street YMCA in Beverly, Massachusetts.” Autodesk praised Windover for using “laser scanners and drones to survey the building’s existing conditions.” And, in 2019, Raafat himself received “Innovator of the Year” prestigious recognition from Autodesk for his work integrating BIM, VR, laser scanning, drones and more into Windover’s work. In addition, Windover is currently improving coordination workflows of construction and design projects with leading-edge drone and BIM work in New England, California, Pennsylvania, Texas and internationally through its IDEA™ Innovation for Design Engineering and Automation Platform.

For Raafat, these awards and the overall success of Windover’s drone operations highlight his company’s core philosophy around uncrewed systems. “It's not only about the latest drone; it's how we process the data and how we embed it into our workflows. It’s about the mindset of innovation to build great things with great people,” he said.

Comments