What does a ‘traditional’ surveyor do?

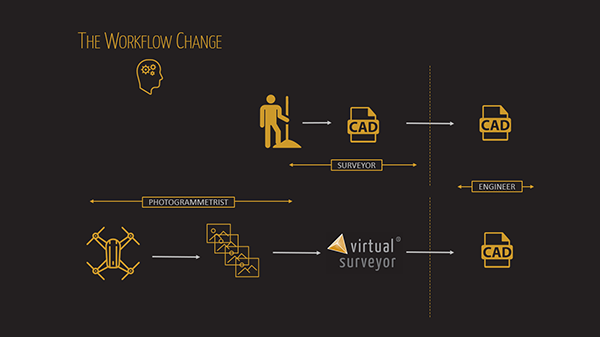

It’s a simple question that professionals will talk through with different levels of detail and insight, but the answer will ultimately explain that surveyors aren’t going to measure a point every centimeter or inch on a project. They’ll look around, scan the area with their eyes, and will model the topography by capturing only the points and lines that matter. This approach creates a lightweight but accurate model that can be loaded in CAD by the design engineers.Virtual Surveyor delivers that same experience but in a virtual environment. Designed to create surveys efficiently from drone data, Virtual Surveyor creates a replica of the real world constructed with the photogrammetry outputs. A surveyor must still capture the significant points and lines, and that’s what Virtual Surveyor delivers. Simply put, Virtual Surveyor allows surveyors to focus on what they do best, which is surveying.We wanted to further explore that concept, and to do so we connected with Tom Op 't Eyndt, Managing Director for Virtual Surveyor. Attendees of the upcoming Commercial UAV Expo will be able to ask Tom their own questions at the Virtual Surveyor booth (#634), but until then, we discussed the business value his product creates, whether or not we’ll see a great deal of consolidation in the future, what advice he has for anyone who sees the potential in the technology and much more. Jeremiah Karpowicz: Can you tell us a little bit about Virtual Surveyor’s genesis and how that does or doesn’t continue to impact the future of the product? Tom Op 't Eyndt: I built my vision on Virtual Surveyor in early 2013. An important inspiration was a talk I had with a surveyor that was one of the first customers of Gatewing. At that time, I had a service company and after I delivered him gigabytes of data, he told me: “Tom, this really looks nice, but I need a CAD file”. I couldn’t find a product that could do that well and I decided to build our own. That day Virtual Surveyor was born, and the child didn’t grow up yet. I will keep on evangelizing this vision. What’s one of the big misunderstandings that surveyors have about drone surveying software? That you don’t need it.Surprising to me, surveyors often stop surveying when they start working with drones. They become a pixel factory instead and focus on photogrammetry only. Someone told me once: “The mesh is the survey!” and he was really convinced about that. But to me, that is the same as saying that a satellite image is a cadastral vector map. The former is data, the latter is structured information. The drone is just a tool that allows us to capture the data. The real work still must be done.This is because many people look at the drone as a ‘toy’, and not at the process as a whole, with a mindset on optimizing the surveying process and saving 80% of costs compared to a traditional job. What can you tell us about your Smart Drone Surveying Software? How does it address or simplify the challenges that surveyors often run into when utilizing survey drones? The challenge with drones is that people must handle gigabytes of pixels, point clouds or meshes while their customers are used to receive lightweight CAD models. So, the challenge is not only handling the data volume but also the nature of the data itself.Virtual Surveyor offers the tools to view those huge data files in an interactive viewing environment. It gives users an experience as if they were on site, boots on the ground.Of course, just viewing info like this has limited value. That would just be a virtual copy of the real world. So, we also include the tools that align well with a traditional survey workflow. These tools allow surveyors to capture the points and lines that really matter, enriched with a layer structure, descriptor and number that are needed to make quality CAD file. What would you say is the main business value that Virtual Surveyor brings to your customer base?Don’t replace your company’s surveyors with photogrammetrists. The learning curve is rather flat. You don’t need to learn surveying, you already know what points and lines matter. You do need to understand what it’s going to mean to integrate a new piece of software into your established workflows, and explore how it’s going to change those workflows for the better. Essentially you can just place points only but when you dig deeper and explore some workflows you’ll see that the saved time can be tremendous. Based on your tutorial that explains the typical surveying workflow, it sounds like Virtual Surveyor is designed to be a bridge between the surveyor and engineer. What kind of feedback have you gotten from users about it?Virtual Surveyor is an essential component to make or break a drone program in any surveying or engineering organization that wants to do land surveying with drones. I’ve seen people throw the data away and start all over again. One person, who was not using Virtual Surveyor, told me: “I wish I would have done a normal survey, I would have done it all a lot faster”. I also had people telling me: “If I had known about Virtual Surveyor before, it would have saved me so much time”.&feature=youtu.beWhat does it mean for surveyors to be able to use the photogrammetry outputs such as orthophotos and point clouds that can be produced by drones as their starting place? What kind of a difference can Virtual Surveyor deliverables make to their workflow and/or process?Modern photogrammetry outputs are intermediate products and have limited direct value for engineers besides situational awareness. Virtual Surveyor starts where modern photogrammetry stops and allows a surveyor to run his last mile. Virtual Surveyor contains the tools to convert the pixels to a lightweight CAD model.I tend to see it as a symbiosis. We need the photogrammetry as inputs, and the photogrammetry engine needs Virtual Surveyor to create what the engineers need. Our current strategy is to develop tools to enable a smooth transition between these different software programs.

What can you tell us about your Smart Drone Surveying Software? How does it address or simplify the challenges that surveyors often run into when utilizing survey drones? The challenge with drones is that people must handle gigabytes of pixels, point clouds or meshes while their customers are used to receive lightweight CAD models. So, the challenge is not only handling the data volume but also the nature of the data itself.Virtual Surveyor offers the tools to view those huge data files in an interactive viewing environment. It gives users an experience as if they were on site, boots on the ground.Of course, just viewing info like this has limited value. That would just be a virtual copy of the real world. So, we also include the tools that align well with a traditional survey workflow. These tools allow surveyors to capture the points and lines that really matter, enriched with a layer structure, descriptor and number that are needed to make quality CAD file. What would you say is the main business value that Virtual Surveyor brings to your customer base?Don’t replace your company’s surveyors with photogrammetrists. The learning curve is rather flat. You don’t need to learn surveying, you already know what points and lines matter. You do need to understand what it’s going to mean to integrate a new piece of software into your established workflows, and explore how it’s going to change those workflows for the better. Essentially you can just place points only but when you dig deeper and explore some workflows you’ll see that the saved time can be tremendous. Based on your tutorial that explains the typical surveying workflow, it sounds like Virtual Surveyor is designed to be a bridge between the surveyor and engineer. What kind of feedback have you gotten from users about it?Virtual Surveyor is an essential component to make or break a drone program in any surveying or engineering organization that wants to do land surveying with drones. I’ve seen people throw the data away and start all over again. One person, who was not using Virtual Surveyor, told me: “I wish I would have done a normal survey, I would have done it all a lot faster”. I also had people telling me: “If I had known about Virtual Surveyor before, it would have saved me so much time”.&feature=youtu.beWhat does it mean for surveyors to be able to use the photogrammetry outputs such as orthophotos and point clouds that can be produced by drones as their starting place? What kind of a difference can Virtual Surveyor deliverables make to their workflow and/or process?Modern photogrammetry outputs are intermediate products and have limited direct value for engineers besides situational awareness. Virtual Surveyor starts where modern photogrammetry stops and allows a surveyor to run his last mile. Virtual Surveyor contains the tools to convert the pixels to a lightweight CAD model.I tend to see it as a symbiosis. We need the photogrammetry as inputs, and the photogrammetry engine needs Virtual Surveyor to create what the engineers need. Our current strategy is to develop tools to enable a smooth transition between these different software programs.

Quantity surveyors generate complex reference surfaces to assess stocks in an accurate and repetitive way.

A line survey created on a motorway interchange

Comments