Instead of having human operators hanging off ropes to inspect huge hyperbolic cooling towers, Sterblue, a software developer for industrial asset inspections and management, developed a fully automated drone solution.

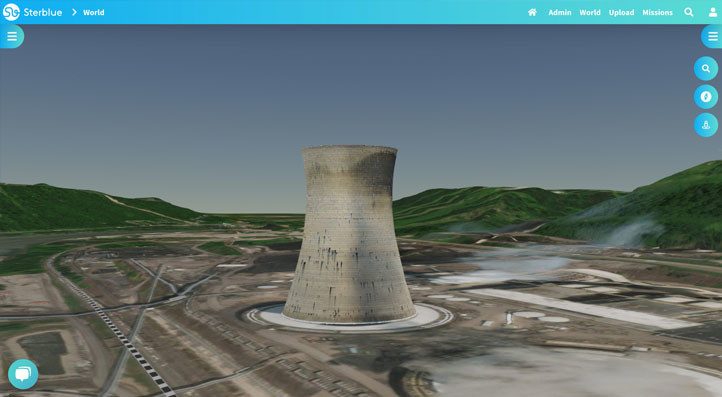

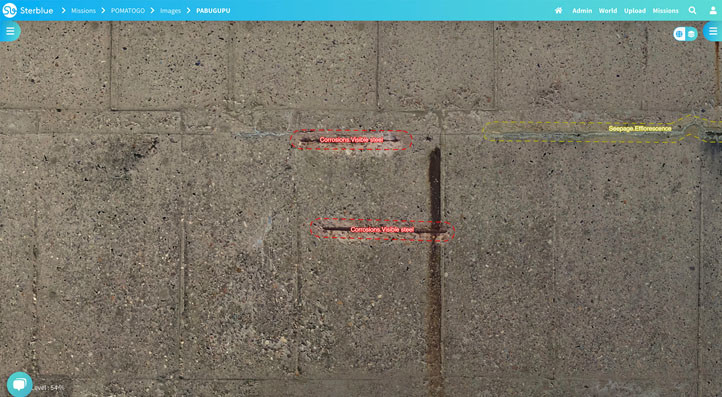

Using an off-the-shelf drone connected to Sterblue’s mobile app, the company performed an exterior inspection of a power plant’s hyperbolic cooling tower concrete shell at a major American utility’s site, which they began working with when they were selected through Electric Power Research Institute’s (EPRI) Incubatenergy Labs program. With a height of around ~330ft (~100m) and a diameter ranging between 164 and 246ft (50 and 75m), inspecting a cooling tower is not an easy task. However, in over three days, Sterblue uploaded around 10,000 pictures to its cloud platform, where dedicated AI models automatically detected and quantified cracks, spalling, and other anomalies in the concrete infrastructure.

Apart from the obvious safety advantages it presents, Sterblue’s drone solution can now inspect an entire cooling tower in less than a day and detect and visualize 0.011in (0.3mm) precision defects, representing a time saving of more than 50% on the overall process. While the company’s focus was mostly on wind turbine and power grid inspections, the cooling tower’s inspection will help them to further expand its product.

Founded in 2016, Sterblue’s platform can process multiple sources of imagery (drone, helicopter, smartphone, satellite), and automates the entire inspection process for industrial infrastructures using drones, 3D navigation algorithms, and AI. Earlier this year, we connected with Sterblue’s CEO, Geoffrey Vancassel, CTO, Vincent Lecrubier; and Ouail Bendidi, Data Scientist, to find out more about their AI solution. Last month, Sterblue partnered with FLIGHTS, a drone service provider in Japan, to launch an online training for wind turbine inspections, which resulted in its first fully remote inspection of a 101m diameter turbine taking only 19 minutes from start to finish.

Now exploring further opportunities to use the technology, Sterblue is already discussing larger inspection initiatives with the hyperbolic cooling tower’s American utility, including the inspection of the utility’s entire fleet before the end of 2021.

Comments