As COVID-19 continues to reshape the way business is conducted, more and more companies are realizing that drones can become force multipliers for essential service personnel and help define a “new normal” for numerous tasks and operations. A brand new drone from Skygauge that allows workers to stay on the ground while visual inspections are being performed in hazardous locations speaks to both of these benefits and much more.

Skygauge recently announced the creation of a drone that is designed for both visual and wall thickness inspections in the offshore and energy sectors. The novel design of the drone is set to address stability limitations that most drones currently utilized for these purposes struggle with, as the tilting the rotors of the Skygauge drone allows it to instantaneously react to wind and other outside forces. This capability gives the Skygauge drone high precision while flying, which is something that was of critical importance to Skygauge CEO and Co-founder Nikita Iliushkin.

“We had to create a completely new control system to take advantage of the new capabilities of this design,” Iliushkin said. “This design enables the drone to be used to exert and receive forces and torques, which has also been a key limitation of existing drones in preventing them from interacting with their environment in a physical way.”

The importance of capturing detailed readings that have to be taken in the same locations in a repeatable manner is as critical as ever. Accurately capturing this data means physically interacting with a structure like a refinery or a wind turbine, which can be a challenge in normal circumstances, and is that much harder during a pandemic.

This short video details the distinctions the Skygauge drone can make for these types of inspections that are focused on critical details like comparing metal thickness readings over each inspection cycle to detect metal thinning.

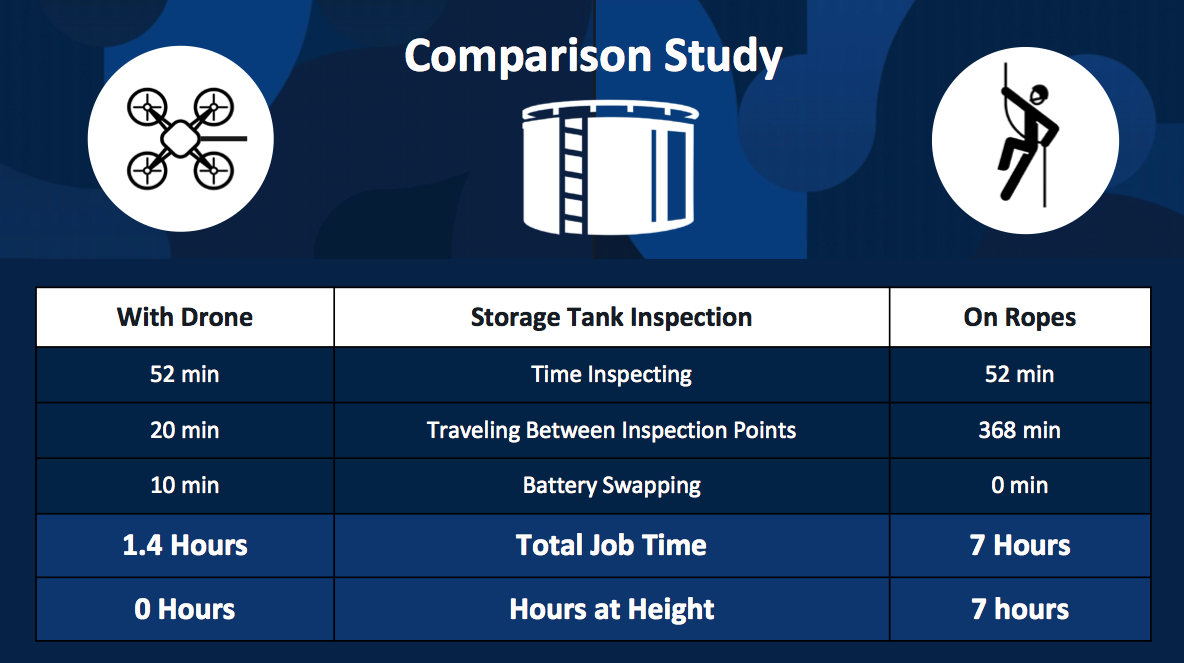

There are challenges associated with the adoption of new tools like the Skygauge drone, but COVID-19 has accelerated the need to adopt innovative technologies and processes. Right now, many inspection processes utilize ropes and scaffolding, which can be unsafe and highly time-consuming. Inspectors can spend most of their time on ropes and traveling between inspection points. That’s part of the reason the Skygauge drone was designed to address the inefficient time and safety expectations associated with current workflows.

“The biggest expense when performing inspections is worker time,” Iliushkin told Commercial UAV News. “We aim to make workers more efficient with their time, as that will reduce overall inspection costs. However, we are not eliminating inspection jobs. We want to give skilled workers specialized equipment that allows them to better address issues before they turn into costly problems.”

To illustrate what it can mean when these skilled workers have such tools, Iliushkin mentioned that the biggest challenge for industrial sites is to minimize unplanned downtime since one day of plant downtime can cost $1m in lost revenue per day. Skygauge drones are designed to perform more basic routine inspections that will free up inspector time for more complicated work and eliminate that downtime.

Creating a holistic solution to address unplanned downtime caused by issues like corrosion is something that can make sense for organizations of all types. That’s part of the reason Skygauge is committed to helping companies better see these differences. The company is open to creating a custom plan for any organization that is looking to incorporate drones into inspections that can eliminate the risk associated with work at height.

To learn more about the Skygauge drone, visit their site.

Comments