Being able to accurately assess the condition of a drone in terms of the maintenance it might need before and after a flight is a critical concern for operators. While there are various programs that provide info about battery life, there really isn’t anything that provides an overall assessment of all the pieces and parts that enable a drone to stay in the air. A new online service, Health Condition Monitoring (HCM), has been created to provide users with an in-depth look at what it means to maintain their UAVs.

SafeDrone by

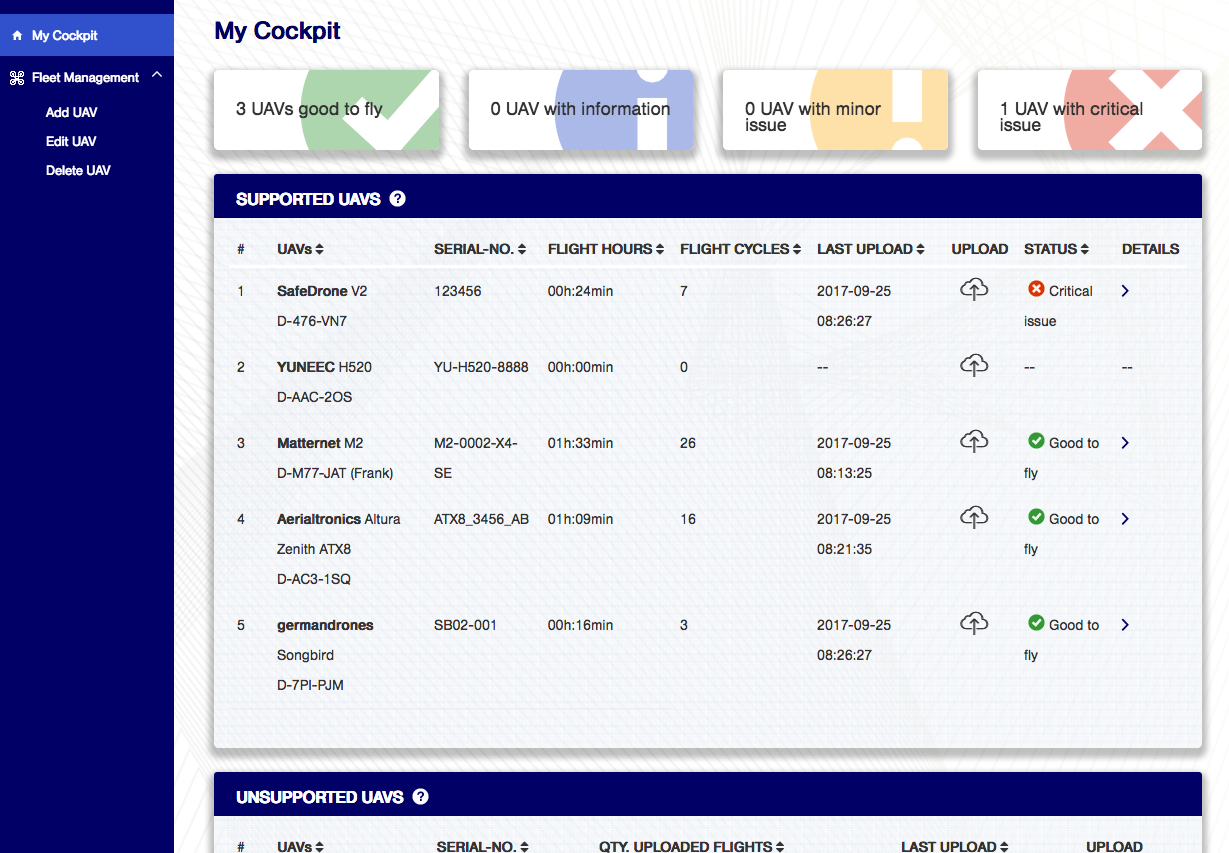

Lufthansa Technik has been launched to minimize the uncertainties and risks involved in unmanned aviation. It’s designed to allow manufacturers and users to monitor the technical condition of their drones and provide detailed information about the overall condition. It is an open platform that will gradually provide all market players with direct access to recognized standards for technology, quality and safety. Batteries, flight controllers, motors and propellers are just a few of the critical drone components that are assessed and reported on.

Ulrich Hoffmann presenting at the 2017 Commercial UAV Show

At the Commercial UAV Show 2017, Ulrich Hoffmann, Project Lead UAV Services Development at Lufthansa Technik AG, showcased the SafeDrone system. He took the audience through the system and showed everyone the critical and detailed information that is available at every step. He also allowed them to see the intuitive interface that allows users to easily see whether or not a drone is good to fly, and if it isn’t, what needs to be addressed.

A few of the advantages the system creates are as follows:

- robust failure detection for critical UAV components

- decreased maintenance costs

- enhanced asset availability

- smarter replacement

- maximized performance

- quality control and industrial benchmarks

We’ve showcased the kind of work Hoffmann has been focused on in terms of

establishing a global UTM, which will enable information and planning for the commercial operator. His efforts in this area are directly relevant to the SafeDrone program, since a global UTM could end up relying on this kind of system to ensure all of the drones that are taking to the sky are doing so in a safe and working condition.

SafeDrone development is initially available for drones from Aerialtronics, germandrones, Matternet as well as the H520 from YUNEEC. Other manufacturers will follow in the coming months. Additionally, the team is already working on enhancements for the product such as preventive warning measures and improved fault identification. All of these efforts as designed to further reduce maintenance effort and improve reliability.

The ability to accurately and efficiently assess the health of a drone in a simple manner has obvious safety implications, but this kind of system could have far reaching impact on insurance and logistical considerations as well. A literal screw loose can be the difference between a major issue and a minor fix, but that’s just the beginning of the opportunities this kind of system could open up for users of all types. It could lead to the creation of industry benchmarks that help determine when and how drones can take to the sky. That kind of standard could end up being used internally within an organization, as well as on a national level via a UTM.

To learn more about SafeDrone,

visit their site. Professional operators should take a look at their

professional provider page, where you can register free of charge.

Comments