According to Daan Arscott, Data Collection Lead at Niricson, “machine learning allows us to be more efficient and cost-effective in comparison to traditional inspection processes.” Arscott based this statement on his experience working on projects involving hydro dams, bridges, tunnels, airfields, and other large concrete assets. Firsthand, he has seen how machine learning is making drone-based infrastructure condition assessments more accurate, efficient, and safe.

“There are a few things that machine learning does that make it a great tool for inspections,” Arscott told Commercial UAV News. “One, it takes a non-biased look at the data that you are collecting. That means it can look at a surface and, if the quality of the imagery is good enough and resolution is good enough, it will be able to identify and quantify all the defects in a non-biased way.”

“There are a few things that machine learning does that make it a great tool for inspections,” Arscott told Commercial UAV News. “One, it takes a non-biased look at the data that you are collecting. That means it can look at a surface and, if the quality of the imagery is good enough and resolution is good enough, it will be able to identify and quantify all the defects in a non-biased way.”

The automation that machine learning facilitates also enhances drone-based inspection work. “These systems let us move one step beyond just digitizing your assets,” Arscott explained. “Sure, it is great to have a 3D model of your structure, but someday somebody is going to have to pour over that entire structure manually and try to identify all the cracks and deficiencies for a proper engineering assessment. Niricson automates this process, for a much faster and higher quality assessment.”

Over the past few years, Niricson has taken on drone-based data collection and inspection projects in its native Canada, as well as in the United States, Australia, and New Zealand. “We see ourselves as a software company that specializes in using machine learning and AI to automatically identify and quantify defects on concrete assets,” Arscott stated. “We’re focused on being a software company, but we invest heavily in the data collection because without quality data, your machine learning and AI isn't nearly as valuable.”

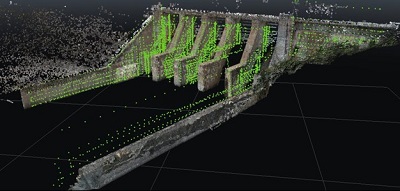

For this work, Arscott stressed the importance of Niricson’s proprietary acoustic sounding payload. “Not only are we simulating the eyes of an engineer through drone-mounted cameras, but we are also simulating the ears of an engineer with our in-house developed acoustic payload,” he stated. “Simulating the traditional concrete hammer test, we are able to physically tap the structure with the help of a drone to identify concrete delamination.”

For this work, Arscott stressed the importance of Niricson’s proprietary acoustic sounding payload. “Not only are we simulating the eyes of an engineer through drone-mounted cameras, but we are also simulating the ears of an engineer with our in-house developed acoustic payload,” he stated. “Simulating the traditional concrete hammer test, we are able to physically tap the structure with the help of a drone to identify concrete delamination.”

In his role at Niricson, Arscott helps coordinate the different systems and personnel that are necessary to inspect and monitor these large assets. “I play a part between our operations pipeline that processes the data and uploads it to our cloud platform for clients and the sales team that is involved in business development and contracting,” he stated.

An essential component of Arscott’s job involves working with drone pilots. “I work directly with clients to hire third party pilots to collect the data” he explained. “This allows us to be global in nature, so we do not have to have service teams set up around the world. Instead, we leverage our relationships and partnerships with third party providers to maintain quality data collection and execute projects with a quick turnaround. In some cases, though, our clients have internal drone teams that we directly support and train in our data collection methodology. This empowers asset owners to collect their own data with their own drones, moving Niricson to strictly a software solution down the road.”

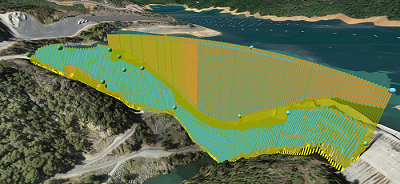

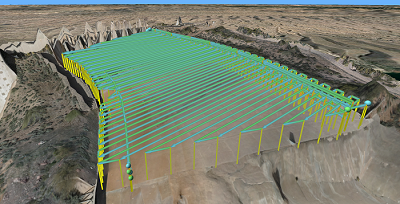

Finding “trusted, qualified pilots” is crucial for these projects, Arscott asserted. “We're collecting really high-resolution imagery to be able to see all these fine defects,” he explained. “We build these super intricate flight plans to collect this data autonomously. So, for these projects, I reach out to pilots who I have relationships with, pilots I can trust to do the work. I'll go to sites, spend a week with the pilots, share my knowledge, and do QA/QC work on that data in the field before I hand it off to our processing team. Then, our internal teams look at 3D models, run machine learning on them, and upload the AI-generated defect maps to our cloud platform.”

Niricson, Arscott reported, has been involved in more than 50 drone-based data collection projects over the past three years. That work has enabled the company to “create a baseline of large infrastructure assets that has quantification data associated with it, so year over year, we're able to go back to a site and rescan the entire structure,” he said. “We can then compare the two data sets to monitor changes through time. Accurate change detection is the real value add with our solution.”

Niricson, Arscott reported, has been involved in more than 50 drone-based data collection projects over the past three years. That work has enabled the company to “create a baseline of large infrastructure assets that has quantification data associated with it, so year over year, we're able to go back to a site and rescan the entire structure,” he said. “We can then compare the two data sets to monitor changes through time. Accurate change detection is the real value add with our solution.”

Niricson’s experience with these sophisticated technologies is spurring growth. “2023 is looking good for us,” Arscott asserted. “We've completed several projects this year already in North America, and we just completed another couple projects in Australia and New Zealand where we are working on the largest, most iconic, and most complex infrastructure assets in the world.”

.jpg.small.400x400.jpg)

Comments