Talk about how UAVs are going to be able to create and enable efficiencies is happening across a variety of industries, but actually doing so is often a logistical challenge. Many people can see and understand that drone technology has the power to make a variety of tasks faster, cheaper and/or safer, but actually doing so isn’t always a simple process. It’s the reason that automatic and automated systems (which can be “drone in a box” solutions) are appealing to professionals in industries that range from construction to agriculture, and why so many people are taking a close look at the solutions from Airobotics.

Their system is intended to be a platform that is fully automated, industrial grade, on-demand and multi-purpose. It’s a system that is designed to open up the next phase of commercial drone automation while also defining what it means to safely operate beyond visual-line-of-sight (BVLOS). When we caught up with Ran Krauss, CEO of Airobotics, one of the things he discussed was how this technology would be used to automatically perform tasks like inspections and surveillance. For a long time, regulation was the biggest thing that kept such things from happening, but Airobotics is working to change things on this front, which is just part of the reason why their solutions are being utilized in a variety of mining, construction and industrial applications across the world.To get a better sense of how these applications are creating efficiencies in these industries, we caught up with Efrat Fenigson, VP of Marketing at Airobotics. We talked with her about the biggest changes that have been taking place in the drone industry, how Airobotics has been able to sort through regulatory challenges in a variety of places, what they’ve done to quantify what it means for their customers to use their technology and plenty more. Jeremiah Karpowicz: It’s been a little while since we caught up with your team to detail what’s happening at Airobotics, and I know things have come along with the company in a big way since then. Before we get into all of that, how would you characterize your company’s growth over the past couple years?

Efrat Fenigson

- Logged more than 30,000 automated drone flights

- Raised $71 Million to date in 3 rounds of funding

- Certified to fly Beyond Visual line of Sight in Australia and Israel, and certified VLOS in US, Chile and New Caledonia, soon to be upgraded to BVLOS.

- Named by The Wall Street Journal as a top tech company to watch (See here for more)

- Partnered with Shapir-Ashtrom for the construction of Israel’s new “Gulf Port” (See here for more)

- Partnered exclusively with engineering company RockBlast to allow Chilean mining companies to utilize Airobotics system (See here for more)

- Senior Google and Facebook Executive Richard Wooldridge joined Airobotics (See here for more)

- Honored by Fast Company as one of the world’s most innovative companies (See here for more)

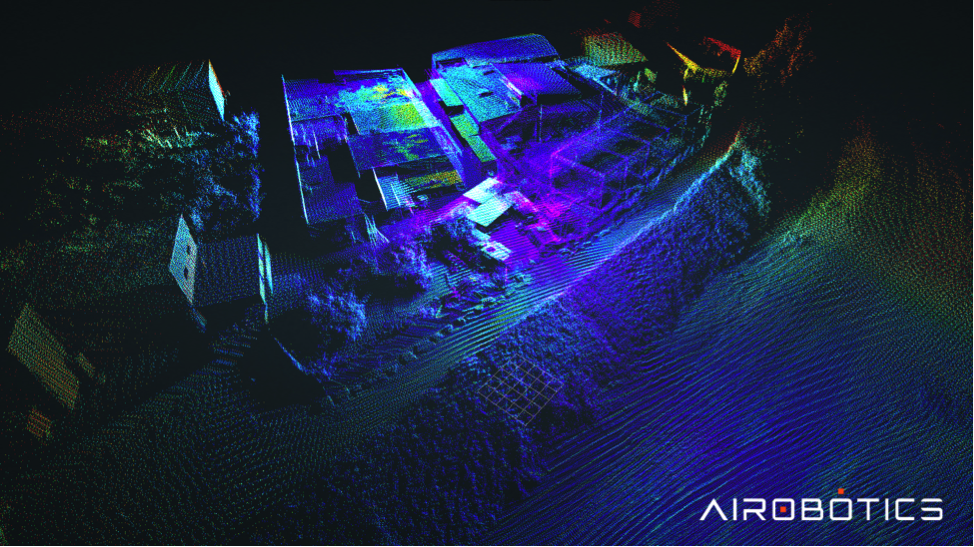

This LiDAR elevation model was created in less than 20 seconds of an Optimus drone flight. The intersection of resolution, accuracy, and coverage capabilities satisfies the required surveying and inspection applications on site.

You’ve clearly had success in figuring out what it can mean for this technology to make sense from a regulatory perspective, and your partnership with a major construction developer to survey a new seaport in Haifa is proof of that. Can you talk a little bit about what it means for Airobotics to be involved in this type of project?

You’ve clearly had success in figuring out what it can mean for this technology to make sense from a regulatory perspective, and your partnership with a major construction developer to survey a new seaport in Haifa is proof of that. Can you talk a little bit about what it means for Airobotics to be involved in this type of project?We’re very excited to be working with Shapir Civil and Marine Engineering Ltd., and Ashtrom Properties Ltd on the Haifa Port project. The seaport and maritime industry can benefit greatly from autonomous drones and it allows our team to continue to enhance our drone’s abilities specifically for this field of work. Ports see an immediate return on investment in drone technology. This is proven by the highly accurate data delivered coupled with the reduced time needed to gather the data, which may take three or four times longer to gather without using drones. Ports can capitalize on their initial investment and recoup costs faster by streamlining tasks and team members, ensuring that no time is wasted. Also, port professionals can ensure the data they're receiving from the drones is being used in the most efficient way to push operations or tasks forward at a faster speed, thereby completing projects ahead of schedule.

What kind of efficiencies is your drone going to be able to create for the project in terms of the approaches to gathering data that the company would have had to otherwise take? Our drones will assist in surveying reclamation areas, monitoring breakwater construction and stockpile measurements, which increases construction accuracy and accessibility, while reducing production costs, and adhering to project timelines. Airobotics sees a major role for drones in inventory control of outdoor bulk material storage areas. Conducting inventory management manually could potentially result in miscalculations or mistakes, not to mention, a lengthy process for employees performing inventory management. By flying over storage areas, autonomous drones are able to calculate inventory in mass quantities with a high degree of accuracy in a time-efficient. The productivity of a port is greatly increased and saves money in potential miscalculations.They can also stop and spend time at a certain location to provide clearer aerial view. This is helpful for navigation in smaller, narrower areas when this ability can contribute to ground based port operations, on top of at-sea navigation. Previously, this kind of data needed to be gathered by people on the ground, which was a lengthier process. They can also assist with navigating ships into the port as they come in and wait for assistance as well as approach a coming ship and navigate it back to land.Employees tasked with performing hands-on inspections by relying on ladders and rigs to large machinery are at huge risk. It also requires machinery to be shut down, resulting in significant financial implications. Autonomous drones offer a professional tool for viewing difficult-to-access areas, giving inspectors a safer, more cost-efficient way of gaining greater insight into operation-critical processes. Additionally, drone inspection significantly reduces the time it takes to inspect, thus saving costs and increasing operational efficiency. Speaking of increasing operational efficiency, you’re also working with RockBlast to bring automated drones to Chile. How have you been able to quantify what it means for the company to utilize this technology and perform a variety of tasks in faster, cheaper and safer ways?Automation has boosted productivity at mine sites by 25% according to a report by McKinsey & Company, and drones are one of the most versatile and cost-effective ways to integrate automation into the industry. Without the need for human pilots, they can operate safely in the most hazardous and remote sites. Airobotics’ automated drones perform a variety of applications, which will be implemented at RockBlast’s customer mine sites, enabling continuous operation of the open pit while retrieving highly accurate data of operational progress. Additionally, RockBlast’s customer mine sites are actively seeking to improve the efficiency and productivity of its operations while creating a safe work environment for its employees and the surrounding area. These applications include:

- Stockpile volumes and end-of-month reconciliation

- Terrain mapping and change detection

- Asset management and scheduling

- Situational awareness and emergency response

- Infrastructure and equipment inspection

- Security and surveillance

What kind of feedback have you gotten from RockBlast and other users in mining when it comes to discussions about what using your technology has meant to their established workflow or process?

What kind of feedback have you gotten from RockBlast and other users in mining when it comes to discussions about what using your technology has meant to their established workflow or process? Horacio Gutierrez Abelaida, CEO of RockBlast identified that Airobotics would be a valuable addition to the needs of the mining industry in Chile. Chile has more than 60 mining sites countrywide and is always looking to increase safety of personnel, operational efficiency and to reduce risk associated with mining operation. In the words of Horacio Gutierrez Abelaida, “Drones have positioned themselves as a technological tool of high value throughout the world, particularly in mining. As part of the growing digitization of information in mining, the data obtained by drones has become an essential factor for decision making in the different stages of the mining process and RockBlast, together with Airobotics, is a part of this new era.”

Do you think your technology has or will change expectations around what it means to operate beyond visual line of sight and even around how to pst effectively gather data for a project?We have been at the forefront of the autonomous drone industry and our technology is making great strides in the BVLOS field. We’re constantly expanding the range our drones can fly from the launch base and the amount of time they can be in the air for. Furthermore, the introduction of new, affordable and compact payloads such as LiDAR are changing the game in terms of frequent, accurate aerial data for surveying and inspection. Due to these advancements, people are now expecting more from autonomous drones in terms of their capabilities.

What advice would you have for anyone that has been looking at drone adoption and feels like they’re ready to transition from “exploring” to “implementing”?If the need exists to increase safety, start collecting vast amounts of big data about the business and introduce operational efficiencies, all in a frequent manner several times a week or even a day, then a fully automated solution is the way forward. With no skills, expertise or certifications for flying drones, any industrial company can now employ an automated drone system and start gaining valuable actionable insights in a short time. Our team is currently visiting various prospects in Australia, US and South America to answer the demand of our growing market.

.jpg.small.400x400.jpg)

Comments