Contributed by Vikhyat Chaudhry, co-founder, CTO, and COO at Buzz Solutions

From Imagery to Intelligence

For the last several years, utilities have invested heavily in new ways to capture data through drones, high-resolution imaging, lidar, thermal sensors, and more. The result is an abundance of visual information about grid infrastructure, from transmission lines to substations. But collecting data is only the beginning. The real value lies in how that data is used.

The next step for utilities is not focused on increasing data capture. It is about translating the wealth of existing visual data into structured insights that inform and trigger operational decisions. This transition represents a critical inflection point where AI and automation shift from theoretical promise to real-world application.

Embedding Data into Workflows

Utilities today are under immense pressure to do more with less. Aging infrastructure, increasing energy demand, the rise of distributed energy resources, climate-related risks, and evolving regulatory expectations all place a tremendous burden on existing systems and teams. Under these constraints, collecting more data is no longer the answer. What utilities truly need is the ability to act on the data they already have.

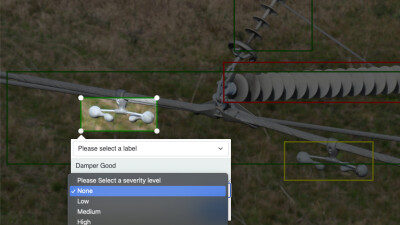

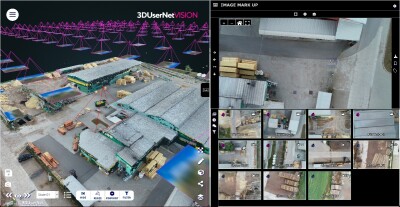

That means making sure inspection data is not only accurate but also accessible and actionable. A foundational step is organizing the data around specific assets. Instead of storing images and inspection notes in folders or siloed platforms, modern systems link each finding directly to a structure like a pole, tower, or substation component. This approach enables a more intuitive understanding of asset condition, supports longitudinal tracking, and provides the necessary clarity to make risk-based decisions.

When corrosion or structural damage is identified, for example, it is no longer enough to include that in a static report or an email. That insight must automatically populate into the utility’s enterprise asset management system as a work order. Ideally, that work order is also prioritized based on severity, urgency, and resource availability. This is how organizations move from analysis to execution.

Risk Prioritization That Drives Action

Operationalizing inspection data means building systems where insights flow directly into planning, GIS and maintenance workflows. This integration enables teams to reduce backlogs, avoid missed issues, and respond to potential failures before they escalate into crises.

A major utility recently shared an experience that underscores this point. They had accumulated thousands of maintenance tickets without a clear system for prioritization. With no ability to sort or rank by risk, tickets continued to stack up, creating operational gridlock. Eventually, one of those unaddressed tickets was linked to a wildfire that caused widespread destruction. The lesson was clear: Without a system to structure, rank, and route inspection findings, even the most diligent data collection efforts can fall short.

Contrast that with a utility that implemented an AI-powered visual inspection platform to support their operations. Within twelve hours, they analyzed over 150,000 images tied to 45,000 transmission towers with over 90 percent accuracy and exported that data into their asset management system. This enabled them to create condition reports, automate work order generation, and reduce manual labor hours significantly. What used to take months became actionable in a single workday. This is the difference between passive data storage and active decision-making.

Breaking Down Silos Across the Utility

Data does not exist in a vacuum. In most utilities, the insights generated during inspections can and should serve multiple departments. Operations, planning, regulatory compliance, safety, and finance teams all have a stake in understanding the health of grid assets.

When inspection insights are organized and shared in a structured way, they create a common operating picture. Planners can better align capital investments with actual field conditions. Compliance teams can streamline audit responses and demonstrate proactive maintenance. Safety officers can track issue resolution timelines and verify that high-risk areas are being addressed. Even executive teams benefit by gaining clearer visibility into infrastructure health metrics that impact reliability and financial performance.

The value here is not just efficiency. It is resilience. A utility with strong internal coordination, where data flows seamlessly between teams, is better equipped to respond to emergencies, allocate resources wisely, and adapt to evolving challenges. Breaking down silos means transforming data into a shared asset, rather than a departmental liability.

Toward Agentic AI and the Future Grid

The next evolution in infrastructure management is the rise of intelligent systems that not only detect issues but also recommend and initiate responses. This capability, often referred to as agentic AI, allows users to interact with systems using plain language queries. For example, a grid operator could ask for the top ten unaddressed defects in a service region or request a breakdown of overdue work orders by voltage class.

But for agentic AI to function effectively, foundational pieces must be in place. This includes structured data, consistent labeling, workflow integration, and human validation. Without these, automation will be unreliable and decisions will remain slow and reactive.

Importantly, this kind of system does not replace human expertise. Instead, it enhances it. Experienced utility professionals bring critical judgment and institutional knowledge that machines cannot replicate. The role of intelligent systems is to free those experts from repetitive tasks, help them see patterns in large datasets, and enable them to focus on complex problem-solving and strategic planning.

Expanding the Impact Across the Grid

Operationalizing data has benefits that extend far beyond maintenance workflows. Structured inspection data can improve outage response by highlighting vulnerable components before weather events. It can help integrate new distributed energy resources by identifying capacity limits and system stress points. It can inform vegetation management by showing areas where overgrowth is likely to interfere with assets.

Regulatory filings also become easier and more accurate. Instead of scrambling to compile inspection reports from different departments, utilities can draw from a single, centralized source of truth. This reduces administrative burden and improves transparency with oversight agencies.

Even customer experience stands to improve. As utilities get better at targeting and resolving issues, reliability metrics like SAIDI and SAIFI improve. Fewer outages, faster restoration times, and more consistent service all contribute to customer satisfaction and trust.

A Roadmap for the Next Phase

Utilities ready to operationalize their inspection data can start by assessing their current systems for gaps in integration, structure, and usability. Do inspection results tie back to their asset and GIS information? Are findings categorized and prioritized? Can insights be easily shared across departments? Are there feedback loops that improve system performance over time?

From there, the goal should be to build toward a unified data and operations ecosystem. One that enables intelligent review, supports GIS integration, feeds into existing planning tools, and evolves with the needs of the grid.

To succeed in this next phase, utilities must think beyond tools and technologies. They need to build cultures of collaboration, prioritize transparency, and continually invest in workforce enablement. With the right approach, they can move from isolated data points to a system of continuous, coordinated, and predictive action.

The future of grid reliability will not be defined by how much data utilities can capture. It will be defined by what they do with it.

About the Author

Vikhyat Chaudhry is the Co-founder, Chief Technology Officer, and Chief Operations Officer at Buzz Solutions, an AI-powered software and predictive analytics platform for detecting faults and anomalies on power line assets and components for power utilities. Prior to launching Buzz, he was leading Machine Learning and AI teams at Cisco Systems. He graduated with a Master’s degree from Stanford University, focusing on energy engineering and data science, machine learning, and AI technologies for the energy sector, specifically in smart grid technologies, demand response, clean energy technologies, and energy efficiency.

Comments