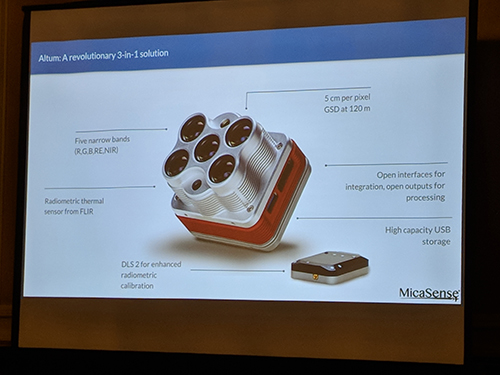

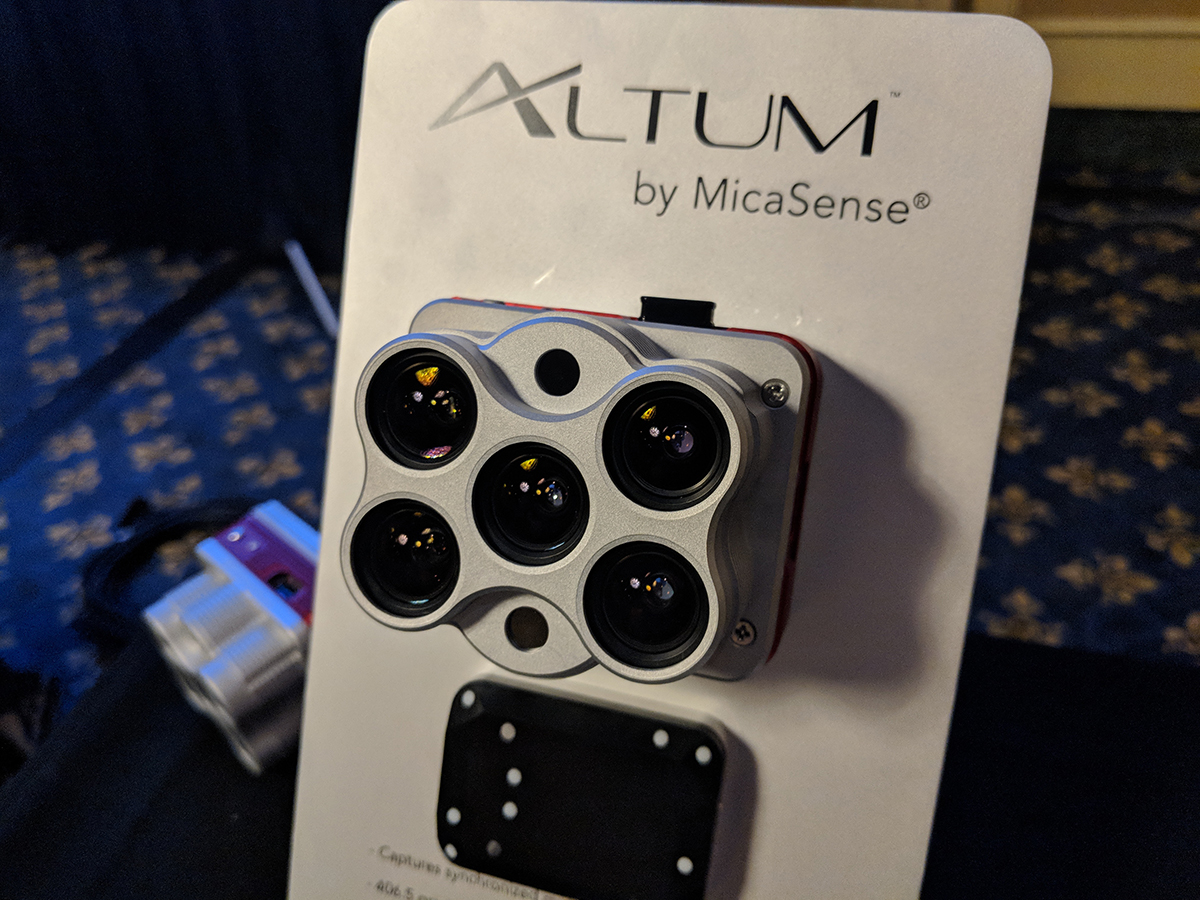

Determining exactly what it means to transform raw data gathered by a drone into actionable information is a process that’s especially varied in agriculture. For farmers and growers, turning data into insight that can drive decisions depends on the crop, location, conditions and many other factors. It’s one of the reasons that solutions like the RedEdge from MicaSense have been able to make such a difference in agriculture, and why the release of the MicaSense Altum could create a whole new paradigm around such processes.

RedEdge was designed to provide a scientific solution that addresses real problems, but Altum takes this commitment to another level. Altum captures synchronized thermal and multispectral imagery in one flight, producing aligned outputs for advanced analytics. An integrated radiometric thermal camera from FLIR and five high-resolution narrow bands means that advanced applications are simpler and easier for users to execute.This incredible usability is personified by Altum’s compatibility with the DJI Payload SDK for the M200 Series drones, but the product’s versatility goes beyond this easy integration. The end game with the Altum was always about being able to capture agricultural and agronomical information that would add real value, but the way it will be able to do so is critical. The combination of thermal and multispectral imagery in one flight enables analysis capabilities that are fundamental in agriculture that could change expectations throughout the entire sector. A 2 in 1 Solution That’s Really a 3 in 1 SolutionIn the process of connecting with users around what they wanted to see from the product that would become Altum, MicaSense recognized the desire for more advanced sensors that still maintained the ease of integration users had come to expect from RedEdge. This desire for a product that could be easily integrated into a workflow while also being utilized with many different types of aircraft was critical, but the usability and flexibility of Altum is about so much more.The time it takes to perform three different flights and capture three different data sets is significant. Changes to the weather in between those flights could push them to the following day or week, and that’s a significant delay when compared to what it would mean to capture everything at once. Usability at this level makes the Altum approachable not only for people who don't have experience with the technology, but also approachable for those who have tried to do thermal and multispectral in the past and it didn’t work out as expected.With Altum, those thermal and multi-spectral layers are synchronized so that the data outputs can be easily aligned. Users can look at a thermal layer in the context of either their multi-spectral or a true color RGB. That gives them a lot of information and directly speaks to the true value of a product being positioned as a 2 in 1 sensing solution, even though it’s much more.“It's really more of a 3 in 1,” said Justin McAllister, Co-Founder and CTO at MicaSense. “For a lot of agricultural purposes, Altum users are going to find that the RGB data that comes out of it is high-resolution enough that they probably won't need to do an additional flight for RGB. Just like with RedEdge, you get RGB plus multispectral that is pixel aligned. That means Altum gives you near-infrared bands plus the thermal layer, which reduces the complexity and provides three separate layers of information.”Many of the people who have been using multispectral sensors for agriculture expressed a desire to utilize thermal data from a processing perspective, but they ran into a lot of roadblocks in aligning that thermal data with their multi-spectral data. Challenges there are associated with that type of data not being data human beings are used to looking at with their eyes. What people see in thermal data doesn’t have a lot of context, and in the plant world, it can be hard to figure out what that context could and should be when it comes to actionable insights.It’s the reason that one of the biggest drivers for MicaSense in building Altum was around connecting this thermal layer to other pieces of information. Synchronizing, calibrating and aligning that thermal layer with the other layers is a tremendously complex process. Altum saves users that trouble by providing a six-band .tiff output that is multi-spectral along with thermal, and that opens up an entirely new value proposition.“We found a lot of users that were flying RedEdge over high-value crops,” said Eric Waters, Director of Business Development at MicaSense. “They'd tend to fly 280-300 feet to get 4cm resolution. With Altum, you can fly at 400 feet, which lets you fly substantially fewer flight tracks and get that 4cm resolution for RGB and multi-spectral. The thermal layer is lower resolution but it's up-sampled in a way that it comes out pixel aligned with all of the other data.”That resolution is a big deal because RedEdge provides about 8 and a half cm resolution at a 400 ft flight altitude, but Altum can give users around 4cm resolution at that same flying altitude. Of course, users that need higher resolution multi-spectral, higher resolution RGB can fly lower. These varied capabilities underscore the accuracy and power of the Altum, but provide just a hint of its flexibility and usability.

A 2 in 1 Solution That’s Really a 3 in 1 SolutionIn the process of connecting with users around what they wanted to see from the product that would become Altum, MicaSense recognized the desire for more advanced sensors that still maintained the ease of integration users had come to expect from RedEdge. This desire for a product that could be easily integrated into a workflow while also being utilized with many different types of aircraft was critical, but the usability and flexibility of Altum is about so much more.The time it takes to perform three different flights and capture three different data sets is significant. Changes to the weather in between those flights could push them to the following day or week, and that’s a significant delay when compared to what it would mean to capture everything at once. Usability at this level makes the Altum approachable not only for people who don't have experience with the technology, but also approachable for those who have tried to do thermal and multispectral in the past and it didn’t work out as expected.With Altum, those thermal and multi-spectral layers are synchronized so that the data outputs can be easily aligned. Users can look at a thermal layer in the context of either their multi-spectral or a true color RGB. That gives them a lot of information and directly speaks to the true value of a product being positioned as a 2 in 1 sensing solution, even though it’s much more.“It's really more of a 3 in 1,” said Justin McAllister, Co-Founder and CTO at MicaSense. “For a lot of agricultural purposes, Altum users are going to find that the RGB data that comes out of it is high-resolution enough that they probably won't need to do an additional flight for RGB. Just like with RedEdge, you get RGB plus multispectral that is pixel aligned. That means Altum gives you near-infrared bands plus the thermal layer, which reduces the complexity and provides three separate layers of information.”Many of the people who have been using multispectral sensors for agriculture expressed a desire to utilize thermal data from a processing perspective, but they ran into a lot of roadblocks in aligning that thermal data with their multi-spectral data. Challenges there are associated with that type of data not being data human beings are used to looking at with their eyes. What people see in thermal data doesn’t have a lot of context, and in the plant world, it can be hard to figure out what that context could and should be when it comes to actionable insights.It’s the reason that one of the biggest drivers for MicaSense in building Altum was around connecting this thermal layer to other pieces of information. Synchronizing, calibrating and aligning that thermal layer with the other layers is a tremendously complex process. Altum saves users that trouble by providing a six-band .tiff output that is multi-spectral along with thermal, and that opens up an entirely new value proposition.“We found a lot of users that were flying RedEdge over high-value crops,” said Eric Waters, Director of Business Development at MicaSense. “They'd tend to fly 280-300 feet to get 4cm resolution. With Altum, you can fly at 400 feet, which lets you fly substantially fewer flight tracks and get that 4cm resolution for RGB and multi-spectral. The thermal layer is lower resolution but it's up-sampled in a way that it comes out pixel aligned with all of the other data.”That resolution is a big deal because RedEdge provides about 8 and a half cm resolution at a 400 ft flight altitude, but Altum can give users around 4cm resolution at that same flying altitude. Of course, users that need higher resolution multi-spectral, higher resolution RGB can fly lower. These varied capabilities underscore the accuracy and power of the Altum, but provide just a hint of its flexibility and usability.  Meeting Users Where They AreThe difficulties associated with integrating a new piece of technology in any industry are considerable, but they’re especially challenging in agriculture, where established workflows and tools can become second nature. It’s why the Altum was designed to meet users where they are with the tools and workflows they’re currently utilizing.“Ease of use is something that's absolutely fundamental,” said Manal Elarab, Director of Enterprise Solutions at MicaSense. “All of us at MicaSense know the variety of users that are out there trying to capture data in fast and efficient ways. To replicate something that would capture data and resemble what you can do with Altum, you're talking about flying a high resolution RGB, getting multi-spectral sensor data and then flying a thermal. So the point of ease of use is huge.”That ease of use isn’t just about reducing the number of flights that are being performed though. People who fly over high-value crops and have issues maxing out their storage will be relieved to discover the Altum essentially offers 128gb of storage with the camera as well as USB 3.0 compatible storage. Users can plug in higher capacity devices, and that ability to adjust and customize Altum as necessary speaks to another level of usability that connects these pieces of technology in an especially powerful manner.From a technical perspective, users typically approach buying a drone and multispectral sensor as separate elements. They might already have a drone and want to add a multi-spectral sensor to it, but there's still some technical knowledge required to put those pieces together. The Altum’s compatibility with DJI PSDK enabled drones directly speaks to where and how the device meets users where they are in their adoption process.“We're definitely baking in the capability to make the workflow super easy from a pilot and data collection standpoint,” Waters told Commercial UAV News. “That ties those pieces of mission planning together with the launch of the aircraft and potentially data streaming to and from the aircraft in flight. There are some capabilities that we're going to take advantage of in the long run for viewing some of the data in the field and then for the recovery of the aircraft and download of the data. The Skyport adapter interface really allows for more seamless movement of the data from the aircraft to other places.”MicaSense has simplified this process to the point where they’ll ship a PSDK enabled kit that will include the camera, light sensor and a mount for it. The camera simply snaps onto the payload connector of the drone as any DJI payload would. The light sensor comes on a DJI standard mount that snaps onto the drone, so there's very little effort for the user to go from an M200 or an M200 RTK to a platform that can now capture RGB, multi-spectral and thermal data simultaneously. That's a huge leap and really takes out a lot of the technical legwork and understanding for the user.All of this means that the process to capture information, run advanced analytics on that data and create different information products is easier than ever. That also makes it more important than ever to ensure the right questions are being asked before this process has even begun.

Meeting Users Where They AreThe difficulties associated with integrating a new piece of technology in any industry are considerable, but they’re especially challenging in agriculture, where established workflows and tools can become second nature. It’s why the Altum was designed to meet users where they are with the tools and workflows they’re currently utilizing.“Ease of use is something that's absolutely fundamental,” said Manal Elarab, Director of Enterprise Solutions at MicaSense. “All of us at MicaSense know the variety of users that are out there trying to capture data in fast and efficient ways. To replicate something that would capture data and resemble what you can do with Altum, you're talking about flying a high resolution RGB, getting multi-spectral sensor data and then flying a thermal. So the point of ease of use is huge.”That ease of use isn’t just about reducing the number of flights that are being performed though. People who fly over high-value crops and have issues maxing out their storage will be relieved to discover the Altum essentially offers 128gb of storage with the camera as well as USB 3.0 compatible storage. Users can plug in higher capacity devices, and that ability to adjust and customize Altum as necessary speaks to another level of usability that connects these pieces of technology in an especially powerful manner.From a technical perspective, users typically approach buying a drone and multispectral sensor as separate elements. They might already have a drone and want to add a multi-spectral sensor to it, but there's still some technical knowledge required to put those pieces together. The Altum’s compatibility with DJI PSDK enabled drones directly speaks to where and how the device meets users where they are in their adoption process.“We're definitely baking in the capability to make the workflow super easy from a pilot and data collection standpoint,” Waters told Commercial UAV News. “That ties those pieces of mission planning together with the launch of the aircraft and potentially data streaming to and from the aircraft in flight. There are some capabilities that we're going to take advantage of in the long run for viewing some of the data in the field and then for the recovery of the aircraft and download of the data. The Skyport adapter interface really allows for more seamless movement of the data from the aircraft to other places.”MicaSense has simplified this process to the point where they’ll ship a PSDK enabled kit that will include the camera, light sensor and a mount for it. The camera simply snaps onto the payload connector of the drone as any DJI payload would. The light sensor comes on a DJI standard mount that snaps onto the drone, so there's very little effort for the user to go from an M200 or an M200 RTK to a platform that can now capture RGB, multi-spectral and thermal data simultaneously. That's a huge leap and really takes out a lot of the technical legwork and understanding for the user.All of this means that the process to capture information, run advanced analytics on that data and create different information products is easier than ever. That also makes it more important than ever to ensure the right questions are being asked before this process has even begun.  What Problem Are You Trying to Solve?To understand what it means to ask the right questions before getting caught up in potential answers around data and drones, let’s focus on something specific like calibration.A lot of users ask if calibration is important, and the answer to that question depends on what someone is going to do with the data. If they’re just looking at something like relative leaf area across a cornfield, calibration may not be all that important. However, if they want to start looking at the leaf area from last week to this week and then look for things that changed, that's where the calibration becomes imperative. It’s a specific type of information that speaks to the essential questions users need to be asking from tools like Altum.“The learning curve for Atlum is not steep, and the power of the information that it's going to provide is considerable, but the end game is really about what value can we add,” Elarab continued. “We talk about insights and maps, but how can we support decisions on a day to day basis? That's about details like finding leaks and discovering areas where trees or leaves or vineyards need attention. Data that is being captured properly is where the real value is because that leads to insights that are going to enable something specific and drive decisions.”Users need to assess if what they did was helpful, which they can do by comparing last week's data and this week’s data in an absolute sense to detect any small changes. This kind of over-time analysis is fundamental from an agronomical perspective. When users have data over weeks or a whole season, they can watch their crops react to soil conditions and environmental conditions over time. They can see things like pest infestation starting to take hold, and can then take action before those things really cause major issues. Figuring where and how these differences are going to be recognized and acted on speaks to the value that sensors like Altum can unlock.“Ultimately, whether it's a long time user or someone just getting into drone technology, the question is all about what problem someone is trying to solve,” McAllister said. “Whether this or any solution is going to be a fit for you is really going to be a function of what type of problem you want to solve. If your problem is going to focus around the things like water stress, the immediate health of the plant today and what today's environment might be doing and how the plant is reacting to today’s environment, that's how a thermal layer is really going to provide key information for you. If you're looking for long-term effects and long-term stress, the multi-spectral data is going to show you how the plants are reacting today to what they've been through in the past few months and weeks as they've grown. The RGB data is always going to provide you with great context, so you're going to be able to look at that and you're going to be able to flip between those quickly in a way that allows you to make key determinations.”Specific answers to questions like why one plant might be cooler than another underscore where value with this technology is being created, and it’s where the promise of drones starts to show up. With the drone and the Altum system, users are able to get to the field and capture data in a timely manner in a way that is less expensive than doing three flights. This combination ultimately enables those users to capture and compare more data, more frequently, in order to better assess what their crops are doing.The combination of high resolution RGB, high-resolution multispectral and thermal is what precision agriculture is all about. It’s a combination that enables the capture and analyzation of three quality layers without a lot of input. It underscores the vision of where and how devices like the Altum can make a difference in agriculture by allowing users to determine where and how these analytics can impact their workflow and not only turn data into answers, but actively drive decisions in an especially powerful way.

What Problem Are You Trying to Solve?To understand what it means to ask the right questions before getting caught up in potential answers around data and drones, let’s focus on something specific like calibration.A lot of users ask if calibration is important, and the answer to that question depends on what someone is going to do with the data. If they’re just looking at something like relative leaf area across a cornfield, calibration may not be all that important. However, if they want to start looking at the leaf area from last week to this week and then look for things that changed, that's where the calibration becomes imperative. It’s a specific type of information that speaks to the essential questions users need to be asking from tools like Altum.“The learning curve for Atlum is not steep, and the power of the information that it's going to provide is considerable, but the end game is really about what value can we add,” Elarab continued. “We talk about insights and maps, but how can we support decisions on a day to day basis? That's about details like finding leaks and discovering areas where trees or leaves or vineyards need attention. Data that is being captured properly is where the real value is because that leads to insights that are going to enable something specific and drive decisions.”Users need to assess if what they did was helpful, which they can do by comparing last week's data and this week’s data in an absolute sense to detect any small changes. This kind of over-time analysis is fundamental from an agronomical perspective. When users have data over weeks or a whole season, they can watch their crops react to soil conditions and environmental conditions over time. They can see things like pest infestation starting to take hold, and can then take action before those things really cause major issues. Figuring where and how these differences are going to be recognized and acted on speaks to the value that sensors like Altum can unlock.“Ultimately, whether it's a long time user or someone just getting into drone technology, the question is all about what problem someone is trying to solve,” McAllister said. “Whether this or any solution is going to be a fit for you is really going to be a function of what type of problem you want to solve. If your problem is going to focus around the things like water stress, the immediate health of the plant today and what today's environment might be doing and how the plant is reacting to today’s environment, that's how a thermal layer is really going to provide key information for you. If you're looking for long-term effects and long-term stress, the multi-spectral data is going to show you how the plants are reacting today to what they've been through in the past few months and weeks as they've grown. The RGB data is always going to provide you with great context, so you're going to be able to look at that and you're going to be able to flip between those quickly in a way that allows you to make key determinations.”Specific answers to questions like why one plant might be cooler than another underscore where value with this technology is being created, and it’s where the promise of drones starts to show up. With the drone and the Altum system, users are able to get to the field and capture data in a timely manner in a way that is less expensive than doing three flights. This combination ultimately enables those users to capture and compare more data, more frequently, in order to better assess what their crops are doing.The combination of high resolution RGB, high-resolution multispectral and thermal is what precision agriculture is all about. It’s a combination that enables the capture and analyzation of three quality layers without a lot of input. It underscores the vision of where and how devices like the Altum can make a difference in agriculture by allowing users to determine where and how these analytics can impact their workflow and not only turn data into answers, but actively drive decisions in an especially powerful way.

Comments