The use cases for leveraging aerial robots for asset inspections are rapidly expanding. We recently covered how drone-based site security can create efficiencies, but the benefits of the technology go beyond security.

Details about how drone-based site security can create efficiencies are readily available, but the benefits of the technology go beyond security. Those same advantages can be enabled for countless industrial inspections that are currently being manually conducted. These are the sorts of tasks that often require engineers to support them, but by utilizing aerial robot fleets, data can instead be seamlessly collected and streamed into workflows. The benefits of using autonomous systems for these tasks create efficiencies but even more critically, they also allow engineers to be engineers.

Similarly, the safety impact that aerial robot fleets can enable is profound. Right now, individuals and teams are putting themselves at risk as part of work that could instead be done by a drone, which not only keeps those individuals out of harm’s way but also frees them up to do more valuable tasks. Drones can perform risky inspections autonomously, reducing the need for human exposure to dangerous conditions. The safety impact is also evident in how the technology can be utilized for autonomous incident response. However, the internal process to adopt these sorts of tools as well as the necessary program investments to make them viable can act as barriers.

Thankfully, the benefits that aerial robot fleets can enable are better understood than ever, making it worthwhile to push past these challenges. But how can stakeholders utilize these innovations to reduce risk for their organization? What does it mean to use them in a way that enables future growth and efficiency? Answers to these sorts of questions will always depend on the industry and application, but implementing best practises like the ones outlined below can empower individuals, teams, and entire organizations.

Consider the Investment's Long-term Value Proposition

Changes around how safety considerations are measured have largely been driven by technological advances and a greater awareness of the costs associated with accidents and inefficiencies, which are significant. According to a recent report by Procore, the annual cost of construction-related deaths, measured in lost production, lost family income, and pain and suffering is over $5 billion. The cost of workers’ compensation from the top five injury causes in construction is nearly $8 billion. In terms of the total cost of work injuries, the National Safety Council (NSC) estimated that to be $167 billion in 2022.

All of which provides context around how and why stakeholders need to approach the adoption of tools that can reduce these human costs in terms of the bottom line and beyond. This understanding is connected to a larger shift towards prioritizing safety in both employee environments and infrastructure that’s taken place over the past few years. Reducing those numbers is a top goal, but what’s the value to an engineer that can use a new tool to avoid lost family income? It's why adoption needs to be driven by focusing on the long-term value and strategic advantages these investments bring.

This perspective allows for a comprehensive evaluation of potential benefits beyond immediate financial returns, emphasizing sustainability, safety, risk mitigation, and competitive positioning. It moves the conversation beyond the costs of today and into the measurable and immeasurable value that will be created in the short and long term.

How can stakeholders effectively position and consider these costs? By sorting out:

1. Long-term Return on Investment (ROI)

Cost vs. Benefit Analysis: Assess the initial costs against the potential long-term savings and revenue enhancements. For instance, a new technology may have high upfront costs but can reduce operational expenses or increase productivity over time.

Time Horizon for Returns: Define a realistic timeframe for when the returns are expected to materialize. Longer-term perspectives are essential for strategic investments like technology or process upgrades.

2. Risk Mitigation:

Reducing Operational Risk: Investments in new tools can mitigate risks associated with outdated processes that may be prone to errors, inefficiencies, or failures.

Compliance and Safety Improvements: New processes often enhance compliance with regulatory requirements and improve workplace safety, reducing potential legal and liability risks.

3. Competitive Advantage:

Staying Ahead of the Curve: Adopting advanced technologies can provide a competitive edge by enhancing product quality, customer service, and innovation.

Market Positioning: Being an early adopter of efficient and sustainable technologies can improve a company’s reputation and appeal to environmentally conscious consumers and investors.

4. Efficiency and Productivity:

Improving Workflows: New tools often streamline operations, reduce the time needed for tasks, and free up resources for other strategic initiatives.

Scalability: Evaluate whether the new tool or process can scale with business growth, supporting larger operations without proportional increases in costs.

5. Employee Impact and Engagement:

Skill Development: Investments in new processes typically require training and development, which can increase employee skills and job satisfaction.

Attracting Talent: Companies using cutting-edge technologies are more likely to attract high-quality talent looking to work in innovative and forward-thinking environments.

6. Sustainability and Environmental Impact:

Reducing Environmental Footprint: Tools that enhance energy efficiency or reduce waste contribute to a company’s sustainability goals.

Regulatory Benefits: Compliance with environmental regulations can prevent fines and sanctions, and support public and governmental goodwill.

7. Stakeholder Communication:

Transparent Communication: Clearly communicate the strategic importance of the investment to all stakeholders, including how it aligns with the company’s long-term goals.

Engaging Stakeholders: Involving stakeholders in the decision-making process can help align expectations and foster support for the initiative.

8. Funding and Financial Planning:

Capital Allocation: Ensure that the financing of new tools does not unduly strain the company’s financial resources. Consider options like leasing or partnerships for cost-effective solutions.

Incentives and Grants: Look for government or industry grants, tax incentives, and rebates that can offset the initial investment costs.

By positioning the investment of new tools and processes within these broader contexts, stakeholders can make informed decisions that align with the company's long-term strategic goals, operational needs, and market conditions. This approach not only justifies the initial expenditure but also highlights the holistic benefits that a drone program will bring to the organization and its stakeholders. What does it mean to go beyond the bottom line though?

Quantifying the Value of Safety

Linking executive compensation to safety goals is a trend that’s come on in a big way over the past few years. Aloca is a major player in the aluminum industry, and they’ve linked 30 percent of their annual incentive compensation plan for certain salaried employees to non-financial metrics that have safety as one of the key areas of focus. After a cyberattack this year, Microsoft is connecting executive compensation to the success of their cybersecurity strategy. However, companies like Delek have approached the alignment of the financial incentives of senior leaders with the safety outcomes of an organization to a whole new level.

Delek US Holdings, Inc. is a downstream energy company with assets in petroleum refining, logistics, convenience stores, asphalt, and renewables. In 2023, the company launched the first US remote operations flight using Beyond Visual Line of Sight (BVLOS) at a refinery, which is a development that was the result of a commitment to safety being a core business priority at the highest levels of decision-making in the company.

This kind of safety alignment has been exemplified by practices observed in companies like Delek as part of a guide that considers the following:

1. Incentive Structure Design

ESG Goals and Beyond: Companies design their incentive programs to include specific safety metrics as part of the performance criteria.

In Delek’s revised incentive program, a significant portion—at least 33%—of potential incentive compensation for executive employees is tied directly to achieving specific Environmental, Social, and Governance (ESG) goals, which prominently include safety objectives.

2. Safety Metrics

TRIR and DART: The safety metrics incorporated into executive compensation can include a variety of quantitative and qualitative targets. By embedding these metrics into the compensation structure, executives are motivated to drive safety performance actively.

Specific examples include a reduction in Total Recordable Incident Rates (TRIR), Days Away, Restricted or Transferred (DART) rates, improvements in safety audit outcomes, or specific safety milestones like achieving zero incidents or injuries.

3. Short and Long-term Incentives

Company Culture and Team Performance: Safety-related compensation can be structured into both short-term and long-term incentives.

Short-term incentives might focus on annual safety performance, while long-term incentives could be aligned with sustained improvements over multiple years, supporting ongoing commitment to safety culture and performance.

4. Transparent Reporting and Accountability

Fostering Trust: Linking compensation to safety outcomes necessitates transparent reporting and accountability mechanisms.

Transparency at this level ensures that there is clear documentation and communication regarding safety performance, fostering trust among stakeholders and reinforcing the seriousness with which the company views safety.

5. Impact on Corporate Culture

Safety Drives Decisions and Resource Allocation: When executive compensation is tied to safety, it sends a strong message across the organization about the value placed on safety.

Tying compensation to safety in this manner can transform corporate culture, as safety becomes a top priority, not only for compliance and operational teams, but also at the executive level. This effort can help ensure that safety considerations are integrated into strategic decisions and resource allocations.

6. Stakeholder Confidence

The Power of Alignment: Aligning executive rewards with safety performance can significantly enhance stakeholder confidence.

With this type of alignment, investors, regulators, and employees see a company that is willing to back up its commitment to safety with tangible financial implications for its top leaders, which can enhance corporate reputation and investor appeal.

By tying executive compensation to safety goals, companies like Delek are quantifying the value of their safety efforts on both sides. This alignment ensures that safety is not just a compliance or operational consideration but also fosters a top-down commitment to safety, which can lead to more robust safety practices, reduced incidents, and a safer working environment overall. This approach not only mitigates risks but also enhances the overall sustainability and ethical standing of the organization.

The cost and safety efficiencies associated with these solutions at an organizational level are real, but how does all of that impact the actual people and teams that are integrating these new technologies into their existing workflows?

Empowering a Team and Organization

The availability of complete end-to-end drone solutions that require less customization is more wide-spread than ever. These solutions can integrate more seamlessly into established workflows, with automated drone-based visual inspections are now expected to be less labor-intensive and more comprehensive. However, resistance to change and integration issues with existing systems when adopting new technologies represent a different type of barrier to adoption.

Overcoming these challenges typically involves the following:

1. Identify Your “Innovation Champion”

Cultivating support: Having an individual or collective “drone champion” allows everyone in an organization to know where to turn with questions and challenges.

Action item: Identify that point of contact enables a flow of information that keeps everyone on the same page. This type of advocate needs to be actively identified and supported from the very top.

2. Training

Cultivate a culture of safety: Training should be the foundation upon which enterprise programs should be built. Ongoing training and specialized education are important for pilots and teams that need to capture extensive data that wasn't previously accessible or require high-risk manual inspections.

Action item: Identify what training is in place and what resources can be utilized to supplement them.

3. Measuring Success: The Bottom Line

Cultivate a focus on ROI: It’s one thing to talk about efficiencies related to time and money, but looking at the specifics on a monthly, quarterly or annual basis showcases exactly where these differences are so profound.

Action Item: Define the one number or one statistic that can be the foundation for an eventual use case that proves the many ways the adoption of this new tool has created value.

4. Measuring success: Beyond the Bottom Line

Cultivate a different way to measure KPIs: Tracking that quantifies the value of proactive site security monitoring efforts, such as preventing theft at oil and gas facilities or construction sites, that extend beyond direct loss measurements is essential.

Action item: Consider how utility companies quantify the costs associated with securing and inspecting critical infrastructure before, during, and after emergency incidents caused by an attack or weather. Being prepared to do so enables cost savings from avoided downtime as well as an extension of the lifespan of equipment due to reduced wear and tear.

5. Celebrating Success

Cultivating team culture: Technology has facilitated changes by providing tools that enhance safety and efficiencies, but celebrating the success of these efforts is critical. Boosting motivation and building confidence enables increased innovation that supports a positive feedback loop that can span across a team and an entire organization.

Action item: Build in defined “celebrating our success” meetings or outings as part of the project schedule that take place after a final deliverable.

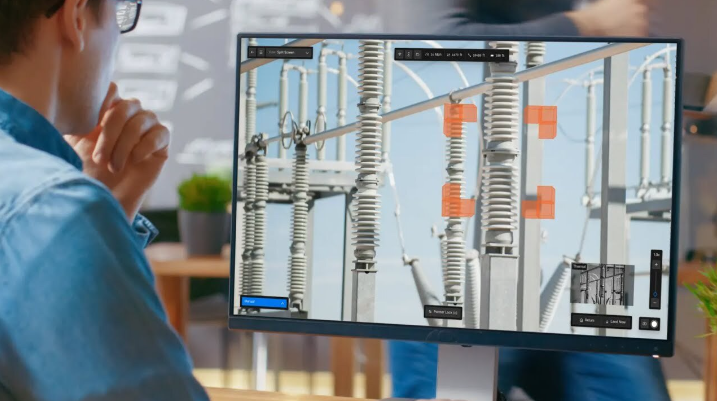

For those looking to adopt new approaches to safety and security, the first step should involve understanding specific risks and the potential benefits of new technologies. Resources to support this journey are readily available, with webinars that outline what substation inspection from an office chair actually looks like to buyer’s guides that help select the right sensors for a mission. These are the sorts of resources that can be utilized to engage with stakeholders to align these new approaches with broader organizational goals and to start with pilot projects to demonstrate value before full-scale implementation.

Comments