For years we have been hearing complaints from drone users and commercial operators about the need to have multiple drones to accommodate multiple missions. It is true that recently some uncrewed aviation manufacturers have added capability to their products to change sensors and in some cases, as in precision agriculture, allow the same aircraft to map the area and then spray the desired chemical compound, but in general drones are very specific to their one mission.

Looking for alternatives to this limitation we found the company Modovolo based in Utica, New York and had the opportunity to talk to Justin Call, CEO and Co-Founder.

“We began our journey towards development of a new drone by thinking long term, variety of missions and production costs. We wanted long flight time, but we also wanted to radically reduce the price of the drone.” Said Justin reflectively, “As the initial work progressed, we noticed how inadequate the 3D printing equipment and injection molding was in relation to our requirements, so, we launched a new development track: that of building our own 3D printers. I know it sounds unorthodox, but doing so, we’ve managed to reduce our production costs by manufacturing our parts four times faster at a fraction of the cost.”

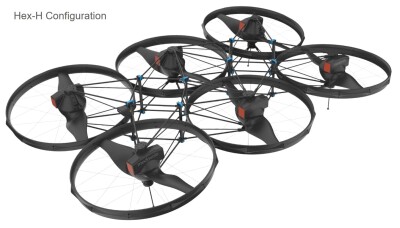

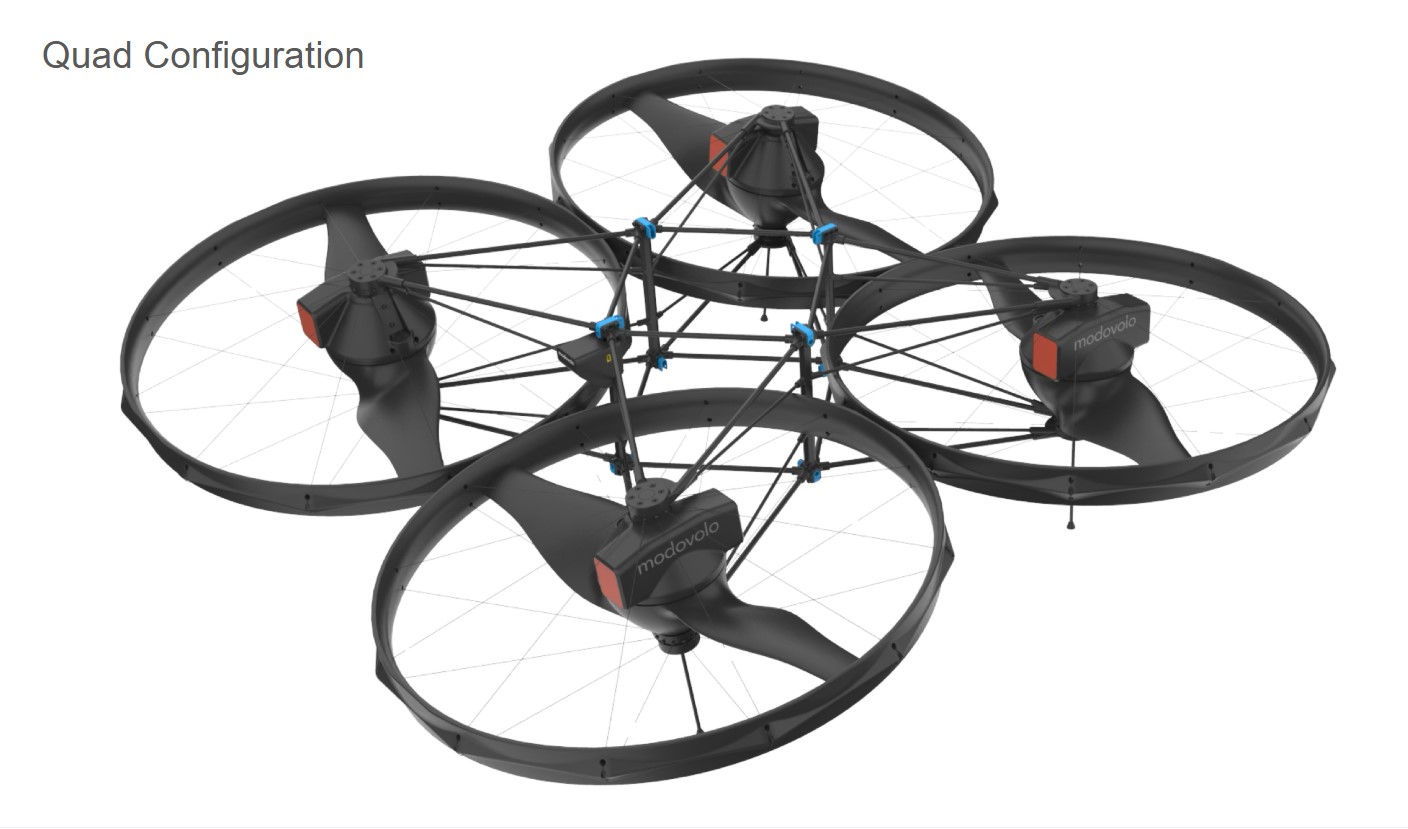

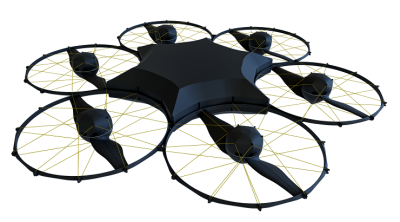

The second development track, apart from the development of their own 3D printer, was the design of a modular drone configuration that can turn a simple quadcopter (4 rotors) into a hexacopter (six rotors) and eventually into an octocopter (eight rotors).

“Early on we heard from drone operators about their frustration with short flight times and being forced to have a mixed fleet of drones, each one to fulfill a specific mission.” Justin said excitedly, “So we based our design on modularity and payload variety and especially on long flight time but at a low price.”

The Modovolo modular drone design stands out as a significant innovation. Unlike traditional drones, which often require extensive modifications for different missions, Modovolo drones feature a modular architecture, allowing users to swap components and configure the drone for specific applications efficiently. This adaptability provides numerous advantages across industries, from logistics to emergency response.

1. Enhanced Versatility

One of the most compelling features of Modovolo's design is its ability to adapt to various tasks. With interchangeable modules, operators can switch between payload types, such as cameras, LiDAR sensors, or delivery compartments, without needing an entirely new drone. This capability makes Modovolo drones ideal for multi-purpose use, catering to inspection, surveying, delivery, and search-and-rescue operations.

2. Cost Efficiency and Sustainability

Traditional drones often require separate models for different applications, leading to higher costs and excessive resource consumption. Modovolo’s modular approach reduces costs by allowing users to invest in a single drone platform and customize it as needed. Additionally, by replacing only worn-out or outdated modules instead of discarding the entire unit, Modovolo drones contribute to sustainable practices in the industry.

3. Rapid Maintenance and Upgrades

Maintaining conventional drones can be time-consuming, often requiring specialized repairs for different components. Modovolo’s modular framework simplifies repairs—damaged modules can be swiftly replaced, minimizing downtime. Similarly, users can upgrade components as technology advances, ensuring their drone remains at the forefront of innovation without requiring a full system overhaul.

4. Scalability for Different Industries

The modular nature of Modovolo drones enables their seamless integration into various industries. In agriculture, they can be outfitted with sensors to monitor crop health. For emergency services, interchangeable payloads can support first responders with thermal imaging or medical supply delivery. Even in military applications, the ability to swap surveillance and tactical payloads enhances operational efficiency.

5. Improved Transport and Deployment

Transporting drones can be cumbersome due to their fixed designs. Modovolo drones, however, benefit from their compact and adaptable structure—modules can be detached and packed efficiently for easier logistics. This feature proves invaluable for rapid deployment in disaster zones or remote areas where traditional drones might struggle with transportation constraints.

“We weren’t originally planning on entering the defense vertical, but we caught the attention of several defense firms and one of the requirements was easy to assemble in the field, so we are designing a mobile manufacturing facility that fits into a shipping container that can be brought into the battlefield and produce drones as needed.” Justin said, “The ultimate goal is to produce a functional drone with a long flight time to low cost ratio, in other words, an aircraft that is easy to produce, fits many missions and is versatile enough to accommodate field production and easy maintenance but at a cost that is a fraction of what the military is paying now for drones. Our next market target is public safety, in an effort to help first responders perform their life-saving missions with versatility and cost-efficiency.”

The Modovolo modular drone design is revolutionizing the drone industry with its adaptability, cost efficiency, and sustainability. By offering a flexible solution that caters to multiple sectors, Modovolo drones not only enhance operational capabilities but also push the boundaries of technological advancement. As the demand for specialized drones grows, modular systems like Modovolo will likely become the standard for cutting-edge unmanned aerial solutions.

Comments