In the rapidly evolving field of unmanned aerial vehicle (UAV) hardware research and development, numerous organizations are working to come up with everything from ways to

increase flight time to enabling measured

increased in efficiency to simplifying

flight plans, all in the name of building better and more efficient drones. While most of these efforts require a distinct approach, one commonality amongst almost all of them is the need for just about every component in a new UAV design to be lighter, smaller and more efficient than its predecessor. In doing so, a drone can see a measured increase in flying time or allow for more sensors and improved performance.

During the recent

NC Drone Summit, we had the opportunity to meet a company that is just entering the UAV market with a technology will enable these increases, all of which are based on their over two decades of experience in the military market. Nanomotion (

www.nanomotion.com) is a Johnson Electric Company based in Israel specializes in the development of

ultrasonic standing wave piezoelectric technology. Simply put, Nanomotion develops and manufactures electric motors that have no moving parts and can stop and restart in microseconds. Their motors are compact and miniature in size, offer extremely accurate and precise movement, high resolution and low settling time, coupled with a dynamic range of velocity and force.

We had the opportunity to meet with Alan Feinstein, President of Nanomotion and a long-time advocate of piezoelectric technology, about what makes his product and company distinct.

“Based on proprietary ultrasonic standing wave piezoelectric technology, Nanomotion’s motors and motion solutions are suitable for a diversified range of applications from optronics to semiconductor, from medical to metrology and other industrial applications,” Feinstein told Commercial UAV News. “Now we are bringing the benefits of this technology to the field of UAVs. Our piezoelectric motors are a lot lighter, are non-magnetic and offer an extremely fast response time to any airborne application.”

Dr. Nir Karasikov, Chief Technology Officer at Nanomotion was also at the event to help attendees see and understand the kind of incredible efficiencies their products can enable. He’s obviously an advocate of their technology, but he’s also a leading scientist in the field of motion devices.

“We have developed a product that we have called Airborne Focus Module and is capable of moving a lens over 20mm of travel with 0.24µm resolution,” said Dr. Karasikov. “This focus module supports a 26g moving mass, exposed to 14.5g vibration at 15Hz (up to 2000Hz), in the direction of motion. Dual Edge-4X motors are used to provide the necessary dynamic driving force and static holding force, to meet this requirement.”

What this means is that Nanomotion solutions can move a camera in repeated start and stops for up to 10 frames per second with absolute precision. This capability allows the same sensor to cover greater areas in less time, without sacrificing resolution.

Oded Sherman, General Manager at Nanomotion, was also at the event, highlighting to attendees where and how they could get their hands on this technology. His more than 10 years experience in the global capital equipment market has provided him with key insights around the present and future of Nanomotion technology.

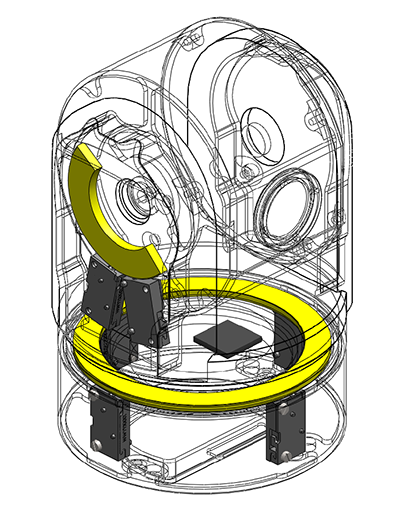

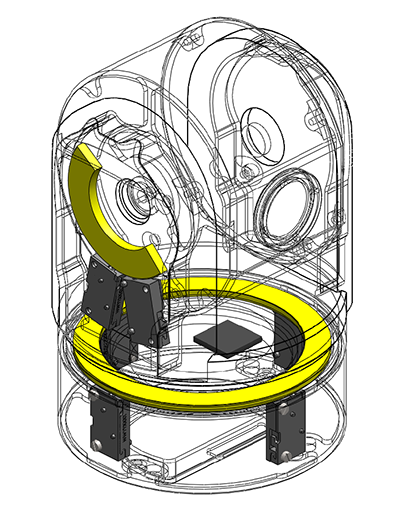

“Now we are launching a revolutionary commercial gimbal, the nG65-D, aimed directly at drone manufacturers who are looking for faster response time and better-stabilized images,” said Sherman. “The nG65-D has stabilized dual (day and thermal) cameras with up to 10 frames per second for panorama/mosaic capabilities and it weighs only 250 grams (8.8 oz).”

From precision multi-axis motion systems to motor components, Nanomotion offers complete solutions to suit just about any motion profile. Their commitment to providing users with creative, innovative motion solutions is one that’s reflected in how the company believes their technology will make a difference for commercial operators in a variety of sectors.

“We firmly believe that bringing our 25 years of experience with motion systems to the commercial drone industry will be a game-changer and new and established manufacturers will be able to benefit for smaller, lighter and more precise motors and gimbals,” Feinstein concluded.

In the rapidly evolving field of unmanned aerial vehicle (UAV) hardware research and development, numerous organizations are working to come up with everything from ways to increase flight time to enabling measured increased in efficiency to simplifying flight plans, all in the name of building better and more efficient drones. While most of these efforts require a distinct approach, one commonality amongst almost all of them is the need for just about every component in a new UAV design to be lighter, smaller and more efficient than its predecessor. In doing so, a drone can see a measured increase in flying time or allow for more sensors and improved performance.During the recent NC Drone Summit, we had the opportunity to meet a company that is just entering the UAV market with a technology will enable these increases, all of which are based on their over two decades of experience in the military market. Nanomotion (www.nanomotion.com) is a Johnson Electric Company based in Israel specializes in the development of ultrasonic standing wave piezoelectric technology. Simply put, Nanomotion develops and manufactures electric motors that have no moving parts and can stop and restart in microseconds. Their motors are compact and miniature in size, offer extremely accurate and precise movement, high resolution and low settling time, coupled with a dynamic range of velocity and force.

In the rapidly evolving field of unmanned aerial vehicle (UAV) hardware research and development, numerous organizations are working to come up with everything from ways to increase flight time to enabling measured increased in efficiency to simplifying flight plans, all in the name of building better and more efficient drones. While most of these efforts require a distinct approach, one commonality amongst almost all of them is the need for just about every component in a new UAV design to be lighter, smaller and more efficient than its predecessor. In doing so, a drone can see a measured increase in flying time or allow for more sensors and improved performance.During the recent NC Drone Summit, we had the opportunity to meet a company that is just entering the UAV market with a technology will enable these increases, all of which are based on their over two decades of experience in the military market. Nanomotion (www.nanomotion.com) is a Johnson Electric Company based in Israel specializes in the development of ultrasonic standing wave piezoelectric technology. Simply put, Nanomotion develops and manufactures electric motors that have no moving parts and can stop and restart in microseconds. Their motors are compact and miniature in size, offer extremely accurate and precise movement, high resolution and low settling time, coupled with a dynamic range of velocity and force. We had the opportunity to meet with Alan Feinstein, President of Nanomotion and a long-time advocate of piezoelectric technology, about what makes his product and company distinct.“Based on proprietary ultrasonic standing wave piezoelectric technology, Nanomotion’s motors and motion solutions are suitable for a diversified range of applications from optronics to semiconductor, from medical to metrology and other industrial applications,” Feinstein told Commercial UAV News. “Now we are bringing the benefits of this technology to the field of UAVs. Our piezoelectric motors are a lot lighter, are non-magnetic and offer an extremely fast response time to any airborne application.”Dr. Nir Karasikov, Chief Technology Officer at Nanomotion was also at the event to help attendees see and understand the kind of incredible efficiencies their products can enable. He’s obviously an advocate of their technology, but he’s also a leading scientist in the field of motion devices.“We have developed a product that we have called Airborne Focus Module and is capable of moving a lens over 20mm of travel with 0.24µm resolution,” said Dr. Karasikov. “This focus module supports a 26g moving mass, exposed to 14.5g vibration at 15Hz (up to 2000Hz), in the direction of motion. Dual Edge-4X motors are used to provide the necessary dynamic driving force and static holding force, to meet this requirement.”What this means is that Nanomotion solutions can move a camera in repeated start and stops for up to 10 frames per second with absolute precision. This capability allows the same sensor to cover greater areas in less time, without sacrificing resolution.

We had the opportunity to meet with Alan Feinstein, President of Nanomotion and a long-time advocate of piezoelectric technology, about what makes his product and company distinct.“Based on proprietary ultrasonic standing wave piezoelectric technology, Nanomotion’s motors and motion solutions are suitable for a diversified range of applications from optronics to semiconductor, from medical to metrology and other industrial applications,” Feinstein told Commercial UAV News. “Now we are bringing the benefits of this technology to the field of UAVs. Our piezoelectric motors are a lot lighter, are non-magnetic and offer an extremely fast response time to any airborne application.”Dr. Nir Karasikov, Chief Technology Officer at Nanomotion was also at the event to help attendees see and understand the kind of incredible efficiencies their products can enable. He’s obviously an advocate of their technology, but he’s also a leading scientist in the field of motion devices.“We have developed a product that we have called Airborne Focus Module and is capable of moving a lens over 20mm of travel with 0.24µm resolution,” said Dr. Karasikov. “This focus module supports a 26g moving mass, exposed to 14.5g vibration at 15Hz (up to 2000Hz), in the direction of motion. Dual Edge-4X motors are used to provide the necessary dynamic driving force and static holding force, to meet this requirement.”What this means is that Nanomotion solutions can move a camera in repeated start and stops for up to 10 frames per second with absolute precision. This capability allows the same sensor to cover greater areas in less time, without sacrificing resolution. Oded Sherman, General Manager at Nanomotion, was also at the event, highlighting to attendees where and how they could get their hands on this technology. His more than 10 years experience in the global capital equipment market has provided him with key insights around the present and future of Nanomotion technology.“Now we are launching a revolutionary commercial gimbal, the nG65-D, aimed directly at drone manufacturers who are looking for faster response time and better-stabilized images,” said Sherman. “The nG65-D has stabilized dual (day and thermal) cameras with up to 10 frames per second for panorama/mosaic capabilities and it weighs only 250 grams (8.8 oz).”From precision multi-axis motion systems to motor components, Nanomotion offers complete solutions to suit just about any motion profile. Their commitment to providing users with creative, innovative motion solutions is one that’s reflected in how the company believes their technology will make a difference for commercial operators in a variety of sectors.“We firmly believe that bringing our 25 years of experience with motion systems to the commercial drone industry will be a game-changer and new and established manufacturers will be able to benefit for smaller, lighter and more precise motors and gimbals,” Feinstein concluded.

Oded Sherman, General Manager at Nanomotion, was also at the event, highlighting to attendees where and how they could get their hands on this technology. His more than 10 years experience in the global capital equipment market has provided him with key insights around the present and future of Nanomotion technology.“Now we are launching a revolutionary commercial gimbal, the nG65-D, aimed directly at drone manufacturers who are looking for faster response time and better-stabilized images,” said Sherman. “The nG65-D has stabilized dual (day and thermal) cameras with up to 10 frames per second for panorama/mosaic capabilities and it weighs only 250 grams (8.8 oz).”From precision multi-axis motion systems to motor components, Nanomotion offers complete solutions to suit just about any motion profile. Their commitment to providing users with creative, innovative motion solutions is one that’s reflected in how the company believes their technology will make a difference for commercial operators in a variety of sectors.“We firmly believe that bringing our 25 years of experience with motion systems to the commercial drone industry will be a game-changer and new and established manufacturers will be able to benefit for smaller, lighter and more precise motors and gimbals,” Feinstein concluded.

Comments