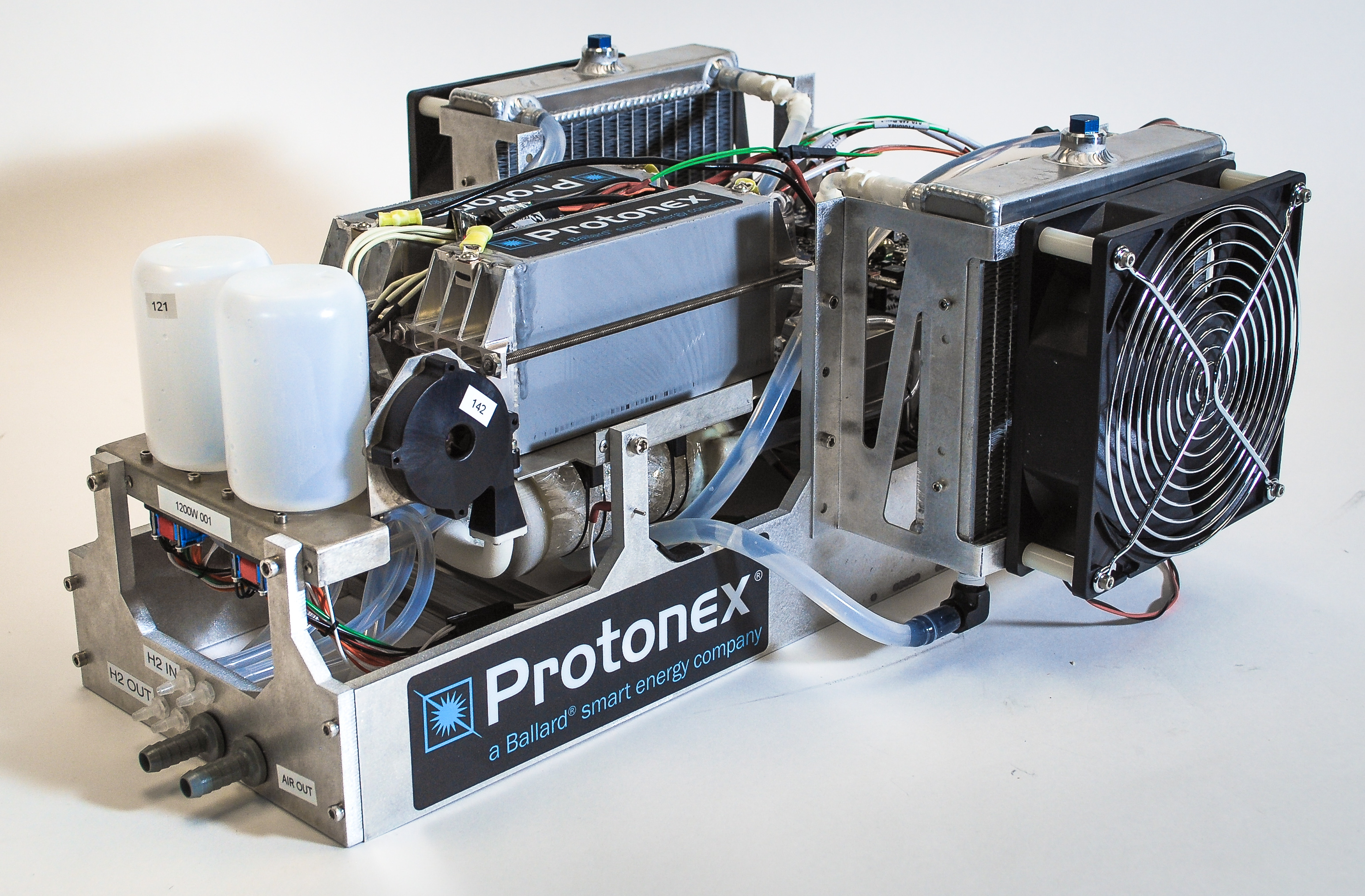

On December 22ndBallard Power Systems (NASDAQ: BLDP; TSX: BLDP) announced that the company has developed a next generation high performance fuel cell propulsion system to power unmanned aerial vehicles (UAVs) or drones.

We’ve been particularly interested in any new developments in hydrogen fuel cell technology given the potential for higher flying time as an alternative to the restrictive current flying time of 25 minutes or less found on most commercially available multi-copters. This next generation fuel cell propulsion system is set to deliver a number of important advances, namely, increased power density, resulting from a new membrane electrode assembly (MEA) design. Additionally, reduced costs that result from a combination of new MEA and one-step fuel cell stack sealing process will also provide major benefits, along with an extended lifetime. The increase in rated power, without any appreciable increase in size or weight, is a particularly significant development for UAV applications.Given the perceived improvements over the technology we first reported back in June 2017, we reached out to Phil Robinson Vice President of Unmanned Systems at Protonex, a Ballard subsidiary, to hear from him directly on the details and potential impact of this announcement. Juan: Do you consider the new technology a breakthrough?Phil: While the technology described in our announcement is important, I’m not sure it qualifies as a “breakthrough”, but is rather part of our continuous improvement. The MEA is where the “magic” happens in a PEM (Proton Exchange Membrane) fuel cell. At Protonex we have traditionally used MEAs from the automotive fuel cell industry, given their very high reliability and good performance. By substituting a Ballard MEA, we were able to increase performance while maintaining reliability and enhancing “operating range”. Juan: Operating range seems to be the challenge for fuel cells, correct?Phil: “Operating Range” is very important for fuel cell power systems, and it is often overlooked. For a fuel cell to operate well, the membrane needs to remain moist (but not too wet) and warm (but not too hot). Different fuel cell design approaches result in vastly different operating environment ranges – air cooled stacks like those offered by others in this space are a little like cold-blooded animals: as long as the environment is warm and moist, they do very well. When it gets hot outside, or cold, or dry, they don’t fare so well. Juan: Does this new technology offer an advantage over the air-cooled systems offered by Intelligent Energy and MMC?Phil: For some applications, yes. Protonex legacy was mainly with the defense world, and the systems were used in hot dry deserts as well as frigid high-altitude locations. Our systems use a liquid cooling system with circulating coolant and a “heat exchanger” (more commonly known as a radiator). This adds some weight and cost to the system, but gives it a much wider “operating range” than most air-cooled systems. Juan: Can you be more specific regarding gains in power output and operating range?Phil: While we already had the widest operating range in the UAV fuel cell industry, the Ballard MEA has widened it even more: it allow us to operate in dryer conditions, and hotter conditions, while generating about 10% more power, so our 600 watt fuel cell system now outputs about 660 watts average. Juan: Does liquid cooling result in an increase in weight?Phil: Of course, everyone would want this wider operating range if it were free – but it has a slight weight cost. That liquid cooling system increases the weight enough that, while our systems are a no-brainer for fixed-wing applications, for multi-rotor copters you need a pretty big platform (typically 6-8 rotors with pretty large props) before a liquid cooled system makes sense. Juan: In the world of commercial applications, more time in the air and longer flights are not really a must-have unless the FAA allows and regulates flights beyond visual line of sight. Do you agree?Phil: Absolutely. Commercial operators today are restricted not by technology but by the regulations that prevent longer flights and BVLOS. The demand for power technologies that would allow longer flights and faster return on investment on aerial platforms will grow dramatically over the next few years as BVLOS missions become commonplace and Ballard is positioning itself to be a leader in the space.As with most issues related to the advancement of Unmanned Aerial Systems, BVLOS keeps popping up as a main obstacle to the deployment of better applications. It is an issue that has captured the FAA’s attention at the highest levels and that the UAS Integration Pilot Program announced by the federal government last month specifically addresses.At the same time that we understand the urge of the industry for flights BVLOS, the safe integration of manned and unmanned aircraft in controlled airspace must also be a priority of every stakeholder. Protonex and the other manufacturers agree with the “Safety-First” approach and support the FAA’s efforts to drive forward quickly yet prudently.Power technologies such as hydrogen fuel cells are contributing to keep our unmanned aircraft longer in the air but ultimately it would be technologies such as detect-and-avoid, proximity sensors and many others that would allow the FAA to open the flood gates of unrestricted UAV operations in controlled airspace.Subscribe

The information you submit will be stored and used to communicate with you about your interest in Commercial UAV News. To understand more about how we use and store information, please refer to our privacy policy.

January 15, 2018

Ballard Announces New Improvements in Hydrogen Fuel Cell Technology for Drones

Comments