For more than a decade, precision agriculture has been one of the most exciting fields in the automation of traditional human activities that, for millennia, have been characterized by wasteful practices.

But the term precision agriculture could be interpreted in a myriad of ways and not all of them are accurate. The Israelis invented the Drip Irrigation Method in 1959 and turned the desert into a garden. That could be construed as the beginning of a technological revolution to bring farming into the 20th century.

Eventually, the proliferation of navigational satellites such as GPS and GNSS would inspire geospatial equipment companies such as Trimble Navigation, Leica and others to develop technologies specifically targeted to making agriculture more precise to save water and avoid dangerous runoffs into the world’s waterways.

Traditional farming equipment was outfitted with highly precise navigation equipment, and fields that were once plowed using just the human eye and inherited instincts were now worked in a technical and systematic manner. This added acres to every field while creating a database where every single seed has X, Y, Z coordinates that could be used to apply water, fertilizers and if need be, pesticide/fungicide.

But after decades of precise agriculture and countless interviews with farmers worldwide, we cannot say with accuracy what the saving have been or even if it was all worth it. All of that changed on Friday July 14, 2023, when we interviewed Jonathan Saborio, a Costa Rican Agronomic Engineer in Colombia who was able to prove, beyond any doubt that precision agriculture saves money, water, fertilizers and pesticides (tons of it, each!).

Saborio left his native Costa Rica in 2016 to work in banana and pineapple plantations in Colombia. What he faced when he arrived in the South American country was discouraging.

“The main problem in the agro-business in Colombia, and I believe in many countries, is absenteeism, or the fact that workers simply don’t show up to work on a daily basis,” Saborio said with concern. “So, the alternative is to add technology to the farm in order to decrease dependability labor. A level of 5% is unsustainable and in Colombia I found levels of 36%. I simply could not grow the crops efficiently with a third of my workforce simply not showing up.”

Saborio and his team were forced by farmhands’ availability, or lack thereof, to look for technologies that would replace human intervention and uncrewed aviation fit the bill perfectly.

“I’d heard about using drones for agriculture, but it was mostly for spraying, so initially I was looking for other alternatives. But in 2018, we bought one and began testing our assumptions,” Saborio said. “If you can’t measure it, you can’t control it and then you can’t manage it. That’s my motto in agriculture. There are two variables you can control: production per acre and cost per acre. Everything else is out of your hands. Things like rain, droughts and availability of resources are issues that you have to deal with as they become available.”

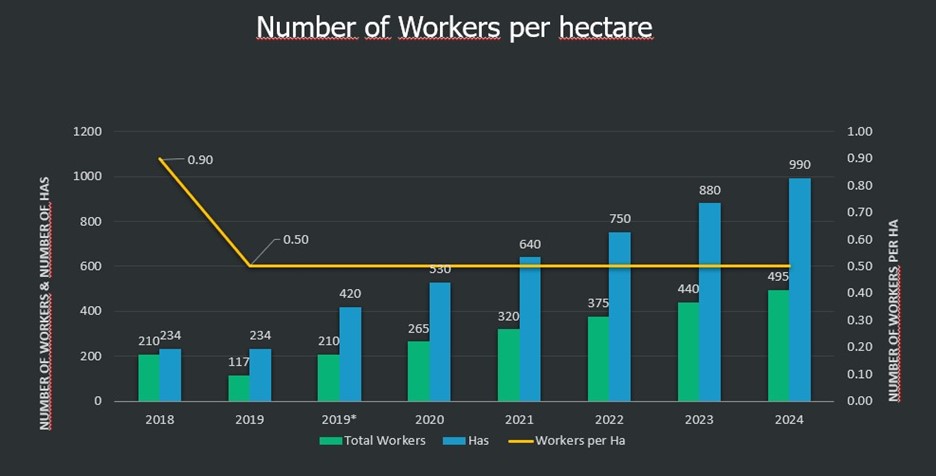

Saborio arrived in Colombia with a large set of benchmarks and important milestones from his professional experience in Costa Rica. For example, he found that one of the most important indicators of good farming practices in pineapple crops is the ration of farm workers per hectare (2.47 acres), which should be .50 or half a worker per 2.47 acres.

“When I had my first statistics after a few months in this particular Colombian field, I was shocked by the number of workers per hectare: .97 or almost one full worker,” Saborio said. “This number, combined with an absenteeism of over 30% made the entire crop strategy completely unviable. We also found that access to certain areas of the field were impassable due to the conditions of the roads and access paths. It was a challenging prospect, but we had to turn it around. Beginning in 2018 with .97 W/Ha, I’m happy to report that through our improvements and the introduction of drones, we’ve been able to reduce that number to the desired .50 W/Ha.”

Traditionally, farming has been done using ground vehicles, and that means that there is a strong dependability on roads and access paths that tend to be rough and sometimes impassable due to mud and topography.

“What we inherited from the previous administration was a situation in which they were trying to manage 650 acres of pineapple as a single entity. We found this to be a mistake and changed it radically,” said Saborio. “We did two things at the same time. First, we divided the 650 acres into lots of 75 acres each and assigned each lot to one person. We selected the best and most consistent workers and promoted them to be ‘Lot Leaders’. We gave them ownership in the managing of the lot and allowed them to select their workers. Then, we equipped the drone with five different sensors including RGB, near infrared, traditional photogrammetry and ultraviolet and then flew each lot to prepare a comprehensive report on the health of the plants and the drainage characteristics of the individual piece of land.”

“One immediate consequence of this strategy was that leaders now had timely information that they needed to improve the efficiency of their individual lots, and that created a sense of pride and ownership that created a healthy environment of competition between them.” Saborio said excitedly. “It’s well known in this business that there are more crop failures for bad administration than the one we attribute to plagues and infestations. With the multi-sensor data, lot leaders now can count the number of plants, determine with inch-accuracy precision the areas that need more water or have drainage problems, and also what specific areas need pesticides or fertilizers. It’s truly a matter of analyzing the recurring data and finding ways to increase crop yield without using more water, fertilizer, and pesticides.”

And here is where Saborio’s story becomes a real turning point for the industry. Even though his experience and analysis are restricted to banana and pineapple plantations, his systematic approach to combining advances in technology with new approaches to human resources management has given him amazing statistics.

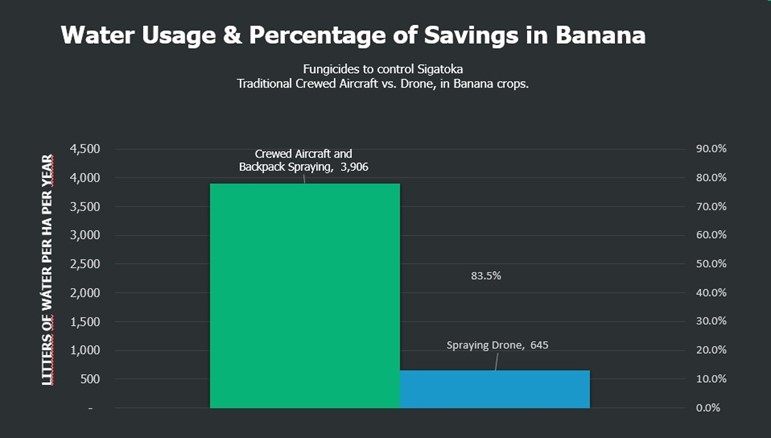

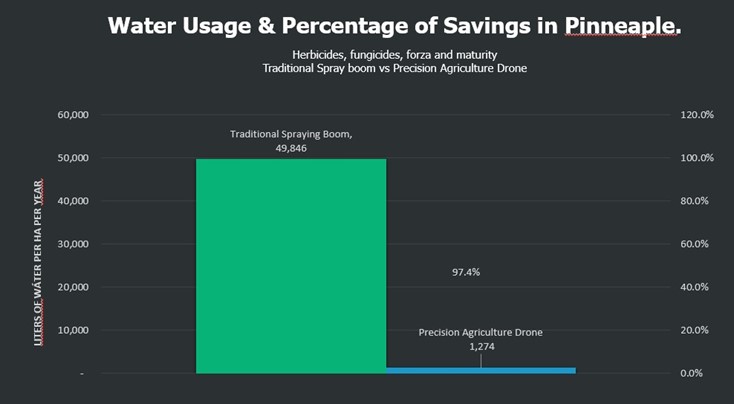

“In water consumption, we have been able to reduce the use of this valuable resource by values that exceed 80% and 90% depending on the crop.” Saborio asserted. “More specifically, when using dry pesticides that require large amounts of water to become usable, the savings are 83% in banana plantations and 97% in pineapple fields. These kinds of numbers are driving the success of uncrewed aviation in our area, and everyone seems interested in switching to this new technology.”

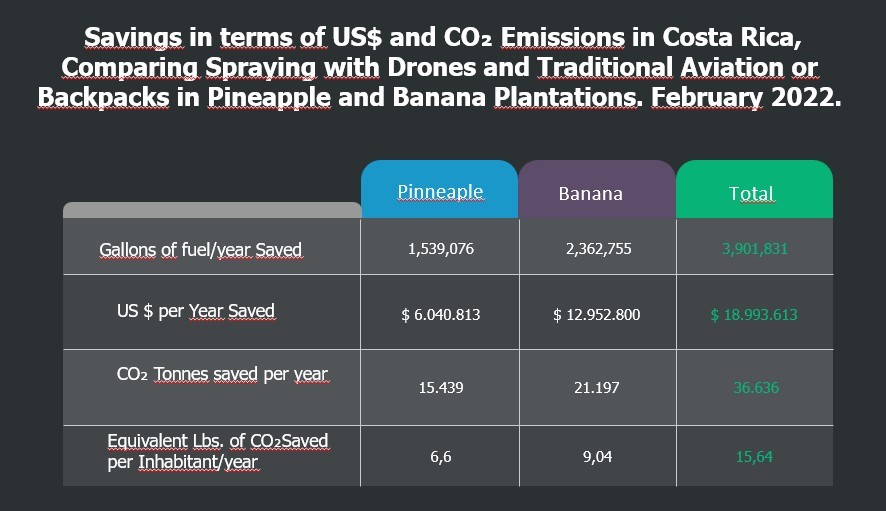

But the savings do not stop with water or the actual dry pesticides and fungicides. The most significant savings, from the environmental point of view, is the reduction in fossil fuel usage.

“By using electric drones, we’ve been able to save millions of gallons of fuel a year by replacing heavy and antiquated diesel equipment with small and environment-friendly aircraft that are easy to deploy, use, and maintain,” said Saborio. “We had no idea that all these traditional technologies such as tractors, mechanical pumps, and traditional aircraft consumed so much fuel in a year, and the savings helped us improve our financial outlook.”

One unintended consequence of these amazing savings in fuel consumption is the fact that Co2 emissions also dropped dramatically, which reduced the carbon footprint of the entire farm.

“When we calculated the number of gallons of fuel that we saved by using electric drones in the property, we were astounded at the number of tons of Co2 that we didn’t spew into the atmosphere. The values were so enormous that we decided to link it to the population of Costa Rica (5 million) and the number made us very happy.” Saborio said. “If the values we obtained in our farm were extrapolated to the entire acreage of bananas and pineapples in the country, it would represent 15.64 lbs of Co2 saved per person per year!”

After carefully analyzing Saborio’s numbers, it is difficult to argue with his enthusiasm for uncrewed aviation in agriculture. Even though his work is restricted to bananas and pineapples, it is easy to imagine a world where these exact savings—or perhaps even better, based on specific crops—can be obtained for the benefit of humanity.

Comments