The issue of flying time for multicopters continues to be front and center as more and more unmanned aerial vehicle (UAV) manufacturers release new products but the specifications of useful time in the air continues to be an issue for operations that need more longevity in order to make a viable business case.

Current battery technology is simply not up to the task of supplying energy to cutting-edge, heavy lift industrial UAVs. Lithium Polymer cells represent significant logistical challenges to operators, ranging from the inability to charge in remote environments to difficulties in transporting them in airplanes and across international borders.

In the past, Commercial UAV News has covered novel approaches to extending useful mission time and more than once we have addressed hybrid technologies, but this time we came across a company, Pegasus Aeronautics, which has an interesting approach in developing OEM (original equipment manufacturer) hybrid powertrains for drones that require multi-hour flight times with heavy payloads.

We talked to Matt McRoberts, co-founder and CEO of Pegasus Aeronautics and Bob Stratton, Corporate Development Manager, who together explained the intricacies of their technology and the advantages it offers UAV manufacturers looking for a competitive edge.

“The hybrid powertrains developed by Pegasus solve all of the issues associated with the use of Lithium batteries,” explained Matt enthusiastically. “By leveraging gasoline or heavy fuels as an energy source, Pegasus platforms can stay in the air for an order of magnitude longer, and do not suffer any of the logistical challenges associated with operating battery-powered systems. Pegasus-powered platforms stay in the air longer, in any environment, with no compromises to logistical efficiency and can carry useful loads of up to 10 kilograms or 22 lbs and/or have flight times exceeding battery capabilities.”

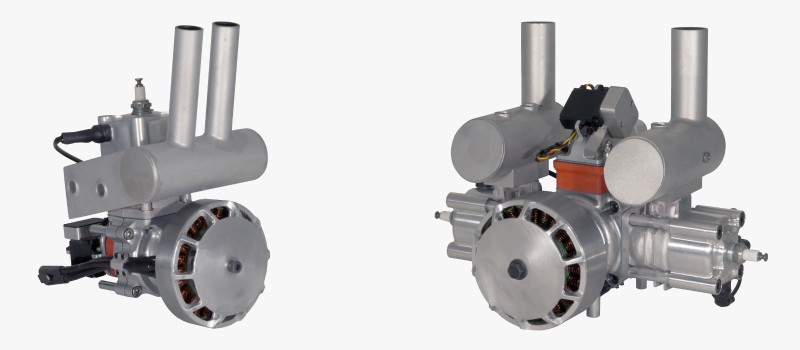

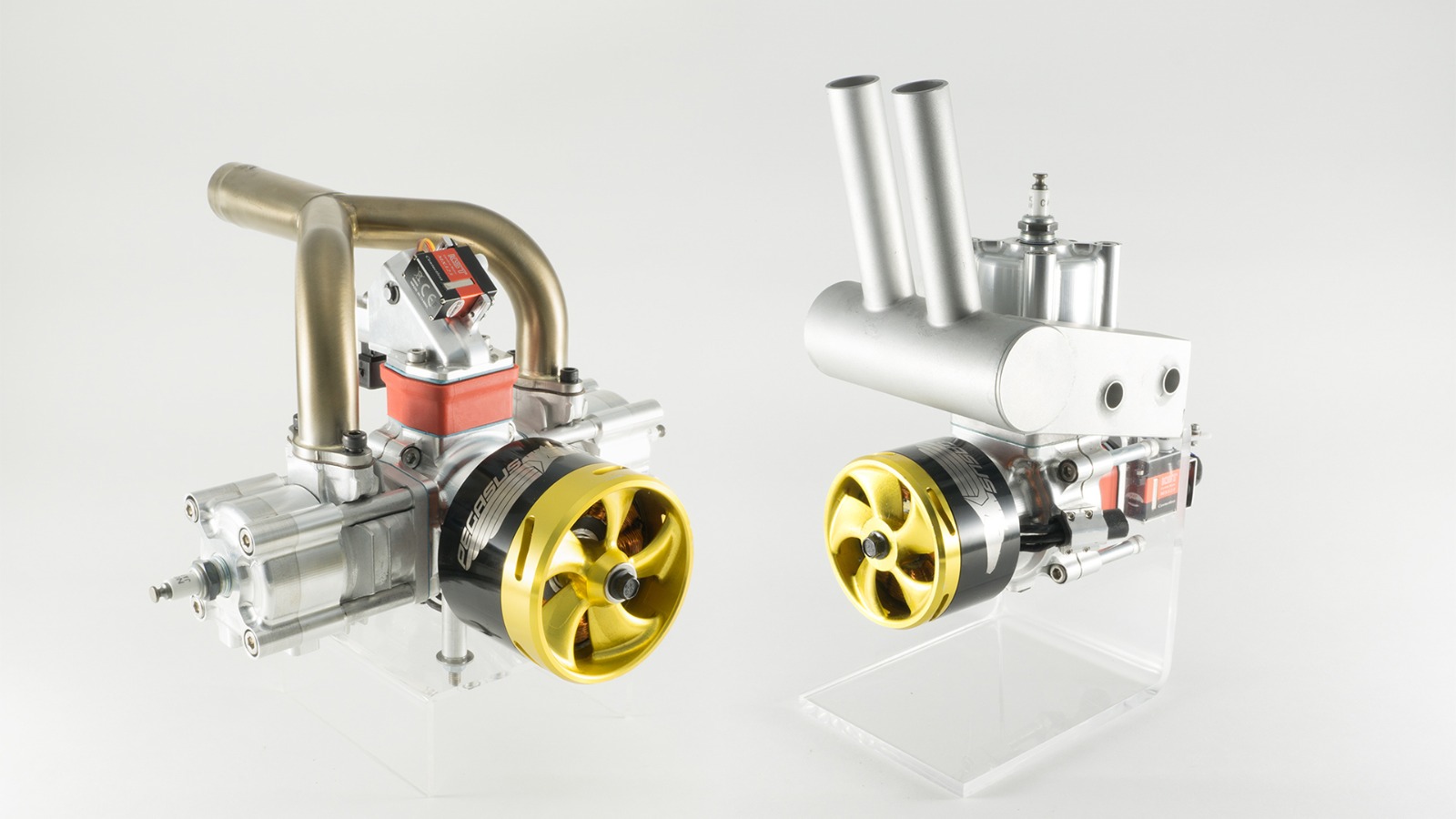

Pegasus Aeronautics designs and manufactures powertrains with industrial environments in mind, capable of operating in a wide variety of climates and include the following industry-leading technologies and capabilities:

- Fuel Injection:

All Pegasus power units are fuel injected to ensure easy starting in any environment or altitude, as well as providing outstanding power output and fuel economy without compromising performance. - Advanced Power Management:

Pegasus automatically powers all UAV systems while managing onboard battery state of charge and all operations of the system. - Raw and Derived Diagnostics:

With onboard diagnostics, Pegasus power units will continuously monitor their own operation, ensuring that they run safely and efficiently at peak performance. - Liquid Cooling:

Actively managing engine temperatures allows for optimal running at any altitude, engine load, and ambient temperature.

“Pegasus power units are the most advanced in the UAV industry,” said Bob confidently. “With the highest power to weight ratios available in the industry, lowest fuel consumption, and with Pegasus’ comprehensive diagnostic suite, UAVs powered by Pegasus are one of the most capable platforms on the market.”

One of the features that caught our attention in the Pegasus design was the fact that it includes a battery on board that serves as a failsafe source of energy in case of a failure of the power generating unit.

“A hybrid drive is like having an enormous battery onboard that gets more and more efficient as the flight progresses, because the unit gets lighter as the fuel is consumed and ‘recharging’ merely requires a gas can,” Bob explained. “This is a great advantage when the operator is attempting to complete a task that requires hours of flying time.”

In order for the powertrains to be so efficient, the design team at Pegasus Aeronautics added sophisticated, yet robust, electronics to each unit, including fuel monitoring, self-evaluation and tuning and computer-assisted fuel management.

“All these onboard systems allow the unit to extract every bit of energy from the lightweight internal combustion engine with minimum waste and maximum efficiency,” Bob stated. “We believe this is the main differentiator relative to our competitors, the fact that we have added a lot of intelligence to the unit, so the drone manufacturers and pilots don’t have to worry about it. They provide the platform and we provide the power to keep that platform in the air for as long as it’s needed to accomplish the task the design called for.”

Regarding the issue of sales and availability of their units to drone manufacturers, Bob told me about their customer Avartek in Finland. An early adopter and BETA tester of the Pegasus units, Avartek sells their ‘Avartek Boxer Hybrid’ drone with Pegasus Aeronautics powertrains. Pegasus is eager to demonstrate the advantages of its hybrid powertrain technology and wants to open the industrial UAV industry to the possibility of carrying heavy loads for extended periods of time.

You can watch the unit in flight in the video below:

Comments