Graffiti is a problem everywhere. When random, garish, often profane messages appear on buildings, bridges, and walls, public service agencies are forced to invest significant time and money to remove them. Resources are diverted, and personnel are often put at risk.

Like many public officials, Michael Gauger, Maintenance Operations Superintendent for the Washington State Department of Transportation (WSDOT) Olympic Region, has been looking for a faster, cheaper, and safer way to solve the problem. Speaking with Commercial UAV News, Gauger described a graffiti removal operation his team conducted about two years ago near the Washington State capitol building in Olympia that demonstrated the challenges involved in the work and led to new way forward.

Like many public officials, Michael Gauger, Maintenance Operations Superintendent for the Washington State Department of Transportation (WSDOT) Olympic Region, has been looking for a faster, cheaper, and safer way to solve the problem. Speaking with Commercial UAV News, Gauger described a graffiti removal operation his team conducted about two years ago near the Washington State capitol building in Olympia that demonstrated the challenges involved in the work and led to new way forward.

A bridge that goes over an interstate highway near the capitol was “tagged” with a large, profane message, and his team had to move quickly to cover it over, Gauger explained. “The only way we could take care of graffiti on that bridge was to utilize a very expensive, hard-to-come-by truck,” he stated. The state only owns six of these vehicles, and they are usually used for crucial bridge inspection and repair work. To paint over the bridge graffiti, Gauger said that the truck was in use for two days, maintenance personnel were put at risk, and the operation cost the state approximately $20,000 to $25,000.

“This got me thinking that there's got to be a better way to deliver paint to the graffiti,” Gauger said. That “better way,” he thought, could involve drones.

Gauger said he has been running a drone program at his department for several years to perform emergency response, inspections, and public safety operations. Based on his experience, he reasoned that an uncrewed system could be adapted to perform graffiti mitigation work.

“It occurred to me there's probably a way to make a drone deliver paint to a high location, and I assumed that somebody was already making it,” Gauger said. After conducting extensive research, Gauger learned about Hartford, Connecticut-based Aquiline Drones, a company that uses uncrewed systems to wash windows.

Gauger watched videos posted online of Aquiline’s vehicles washing windows of skyscrapers in New York City. “It looked to me that if you could make a drone spray window washing fluid, you could probably make it spray paint,” he said. “So, I called them up and just told them who I was, where I'm from, and what I needed.”

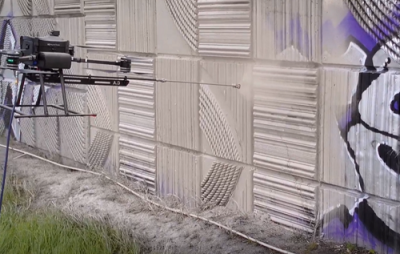

In time, Aquiline developed a prototype graffiti-fighting drone. Adapted from the company’s Endure vehicle, this medium-sized, eight rotor drone uses an airless paint sprayer that is tethered to a paint supply on the ground. Gauger trained on the vehicle and offered feedback. Today, Gauger’s team is field testing the drone to determine if it can be used on a wider scale in the future.

To perform drone-based graffiti mitigation with this new drone, a two-person team comprised of a drone operator and a person handling the paint supply is deployed. The system is currently being field tested to remove graffiti in hard-to-reach places and is showing promising early results. At this time, the team is collecting valuable information that will lead to process improvements, and, critically, has the potential to make graffiti removal safer for WSDOT personnel.

To perform drone-based graffiti mitigation with this new drone, a two-person team comprised of a drone operator and a person handling the paint supply is deployed. The system is currently being field tested to remove graffiti in hard-to-reach places and is showing promising early results. At this time, the team is collecting valuable information that will lead to process improvements, and, critically, has the potential to make graffiti removal safer for WSDOT personnel.

“It takes a long time to deploy fall protection,” Gauger stated. “Using this drone will never require fall protection. It will never require a man in a basket. It will never require a crane to lower people down. So, this system could really lead to the reduction of risk to our employees.”

In the coming months, Gauger and his team will be collecting information about the new system to refine processes. “Every time we fly, we learn new things,” he said. “Sometimes, it's about how we are going to manage the drone out on a right of way amongst traffic. Sometimes, we find out that a little change here or a little change there will make the drone operate better.”

In addition, Gauger said, “offline” work has led to improvements in the mechanical aspects of the drone, the paint spraying system, and software that guides operations and collects data.

“We’re trying to come up with the very best product to do this job,” he said. “We’ll do research throughout the summer, and the findings from our research are due by the end of the year.”

Comments