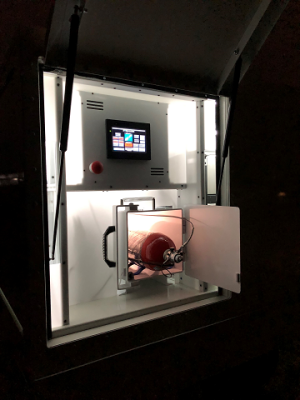

As part of its ongoing effort to advance the adoption of hydrogen technology in the uncrewed systems market, H3 Dynamics has introduced the H2FIELD-1, a hydrogen station that can produce hydrogen in the field to power airships, multi-rotors, VTOL systems, and fixed wing systems.

According to H3Dynamics, the H2FIELD-1 “solves fundamental hydrogen accessibility in remote areas, unlocking a major logistical barrier for a growing base of hydrogen drone operators in industrial, defense, or even academic sectors.” The station can be transported by trailer to bring hydrogen production to different locations. Or it can be connected to solar panels and operated as a permanent installation.

According to H3Dynamics, the H2FIELD-1 “solves fundamental hydrogen accessibility in remote areas, unlocking a major logistical barrier for a growing base of hydrogen drone operators in industrial, defense, or even academic sectors.” The station can be transported by trailer to bring hydrogen production to different locations. Or it can be connected to solar panels and operated as a permanent installation.

“Sustainability in a field environment is a ‘must have’ for the defense and large-scale commercial UAV operations in remote and austere areas,” explained Jarat Ford, General Manager, H3 Dynamics North America. “We designed the H2FIELD-1 to enable sustained 24-hour operations and reduce the burden of costly fuel logistics. Simply put, we enable hydrogen on demand and make it as we go."

To learn more about the H2FIELD-1, Commercial UAV News spoke with Ford. We discussed the station’s features and capabilities, how it will help drone-based commercial operations, and more.

Commercial UAV News: What are the major features of the H2FIELD-1, and how does it support uncrewed systems?

Ford: We designed the H2FIELD-1 as a compact, vehicle-tractable trailer unit. The station follows hydrogen operators to the point of operations, typically in remote places to produce hydrogen on-site for hydrogen drone operations. It’s a simple-to-use system that fills small UAV storage tanks automatically. In goes the empty tank, out comes a full one in less than 15 minutes. Hydrogen is created using electricity from the vehicle or an outside power supply to separate water into hydrogen and oxygen. An onboard compressor pressurizes and transfers the gas to the UAV’s storage cylinder located inside the trailer system. A hydrogen powered UAS using pressurized hydrogen storage tanks can fly up to 10 times longer than using batteries alone, depending on the configuration. Hydrogen UAVs can be in the form of a VTOL, multi-rotor, fixed wing or airships—and typically use a similar H3 Dynamics hybrid fuel cell electric power system—each one has different flight characteristics and power usage profiles.

Commercial UAV News: What are the benefits of using hydrogen for commercial UAV operations?

Ford: Hydrogen UAVs offer an intriguing 3-to-30 times more flight endurance capability compared to batteries. Given that batteries are a major operational limitation in this industry, one would think everyone would have switched over to this technology already. That being said, the key enabler or barrier to this market is access to hydrogen itself. The number one question from those operators or drone manufacturers looking to make the switch is "where do I get the hydrogen." Given such flights are typically taking place in remote areas, industrial gas companies can’t be relied upon. H2FIELD-1 solves the problem by bringing a “do it yourself” hydrogen capability in the field, at the point of operations. H2FIELD-1 has been a pretty big missing link in the space, which hasn’t seen such a solution for 15 years since research on H2-powered UAVs started.

Commercial UAV News: What kinds of commercial projects or operations can benefit from the H2FIELD-1?

Ford: As with many UAS future technologies, our H2FIELD-1 was initially designed for defense, public safety, and security sectors as these organizations have mature and well established UAS programs. Impressed with the endurance that hydrogen provides, they needed the ability to make their own hydrogen in a field environment and sustain operations without interruption. Say you need to operate, hundreds of miles away from civilization; this is the only system that can help provide an electric fuel for silent ISR aircraft hovering above the field of operation. The same system can then also be used to store hydrogen for other small power items, such as small power generator, lighting, and communication or satellite devices set on hills or mountain tops.

On the commercial side, H2-FIELD-1 is ideally suited to support hydrogen powered drones in direct support of large-scale mapping operations in mining, very large agricultural spaces which need long coverage. There is already a need for such devices in mining operations—some of which have the size of small countries. Simply put, often the assets being inspected are in remote areas where crews spend days or weeks at a time. Hydrogen is likely not available, so the H2FIELD-1 allows the on-demand production of fuel needed for extended flight, accelerating the time it takes to cover these large areas with a battery-based UAS.

Commercial UAV News: What has been the market’s response to the H2FIELD-1?

Ford: The response has been extremely positive from both defense and commercial markets. We have exceptionally high demand from the defense sector especially as hydrogen drones started to appear in various programs. We expect the commercial sector to follow as we are already leading the effort to convert the battery powered UAV industry to hydrogen, one manufacturer at a time.

Commercial UAV News: What’s next for H3 Dynamics?

Ford: H3 Dynamics is already working on a liquid hydrogen version of this trailer system which would increase endurance by a further 30 times relative to batteries. One of our research programs in Europe is to cross the South Atlantic for the very first time (a 33-hour flight duration) with this capability already being ground-tested in one of the major aerospace engineering institutes in France, located in Toulouse.

Comments